CNC Vertical Wire Saw Machine for High-Precision Cutting

LSSJ-800

This CNC wire saw machine cuts both straight lines and complex curves for memorial stones with ±1mm accuracy. Its vertical design uses 40% less floor space than horizontal machines, perfect for small workshops with limited space. Processes granite, marble, basalt, limestone, sandstone, and engineered stone into detailed tombstones, crosses, sculptures, memorial plaques, and architectural elements with smooth surfaces that require minimal polishing.

Compatible Materials & Products

Precision Cutting Across Multiple Stone Materials for Premium Memorial Products

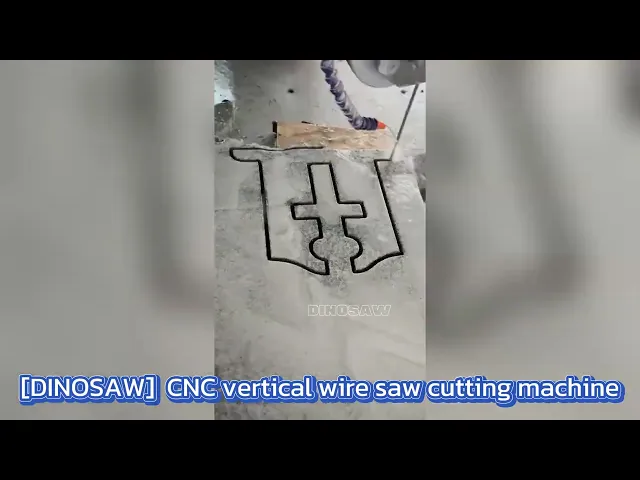

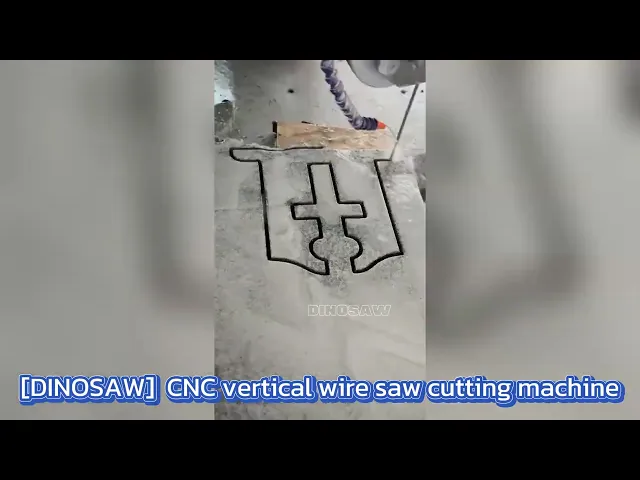

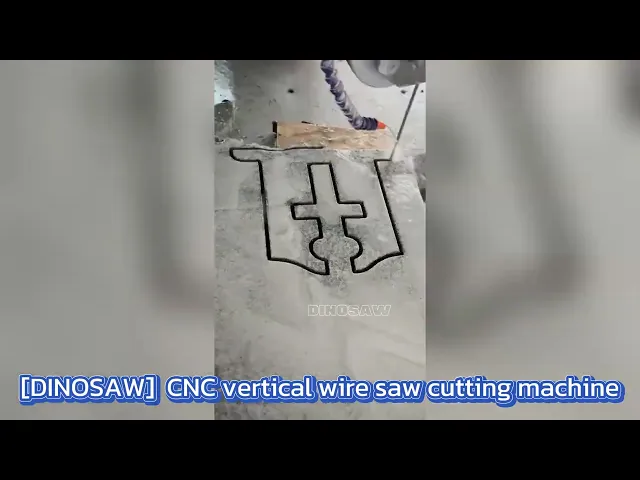

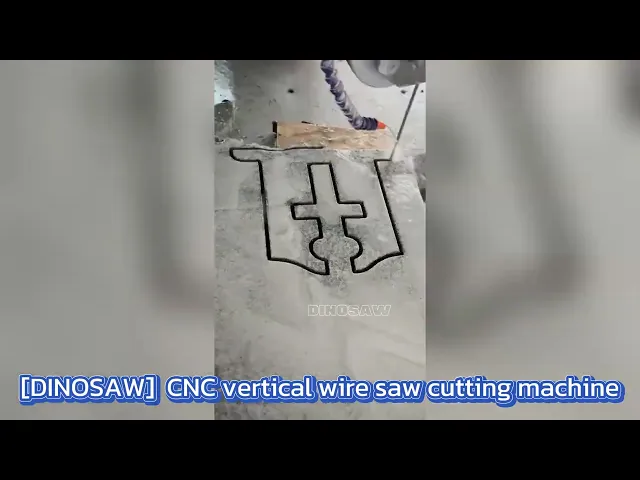

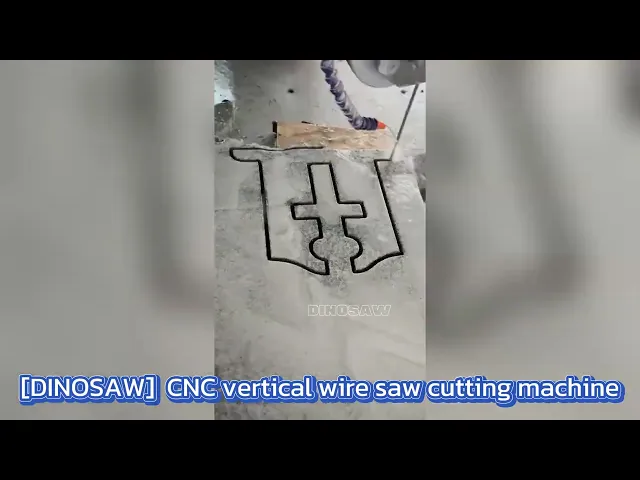

▶ Product Demo

Granite ❯ Tombstones

Marble ❯ Crosses

Granite ❯ Monuments

Basalt ❯ Decorative Elements

|

|---|

DINOSAW CNC Vertical Wire Saw Machine Video |

▶ Product Demo

Granite ❯ Tombstones

Marble ❯ Crosses

Granite ❯ Monuments

Basalt ❯ Decorative Elements

|

|---|

DINOSAW CNC Vertical Wire Saw Machine Video |

Consult DINOSAW Material Expert →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Elevate your custom monument capabilities →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Elevate your custom monument capabilities →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Elevate your custom monument capabilities →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Elevate your custom monument capabilities →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Specs and options

Specifications customizable upon request.

Model | Unit | LSSJ-1900-9H |

|---|---|---|

flywheel | mm | 2x900 |

Max.cutting height | mm | 800mm |

Trimming diameter range | mm | 1600~1900mm |

Wire diameter | mm | 4~8.8 |

Main motor power | kw | 11 |

Overall dimensions | m | 3.69x1.9x3.6 |

Contact DINOSAW technical team for details →

Discover why DINOSAW diamond wire saw is the ideal solution for stone memorial profiling.

Big Cutting Power, Small Footprint

Space-Saving Design

Vertical structure reduces footprint by over 50% compared to horizontal configurations.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Inqury for Details →

Space-Saving Design

Vertical structure reduces footprint by over 50% compared to horizontal configurations.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Integrated Frame Design

Easy installation - simply secure the machine body to begin operation.

Remote Operation

OTA technology for remote updates and maintenance support.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

FAQs

Common Questions About Vertical Diamond Wire Saw Machines

What types of stone can this diamond wire saw machine cut?

What types of stone can this diamond wire saw machine cut?

How does a vertical wire saw differ from horizontal models?

How does a vertical wire saw differ from horizontal models?

What is the maximum cutting capacity of this machine?

What is the maximum cutting capacity of this machine?

How long do diamond wires typically last?

How long do diamond wires typically last?

What maintenance does the machine require?

What maintenance does the machine require?

Can this machine cut curved or irregular shapes?

Can this machine cut curved or irregular shapes?

Need more assistance? Click to contact DINOSAW →

Certifications & Standards

Global Leader in Industrial Machinery & Diamond Tools Manufacturing

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Bridge Saw Machine

Precision Stone Cutting Bridge Saw for Tombstone Pre-cuts stone slabs to required thickness and dimensions before wire saw shaping. Provides stable platform for accurate straight cuts with 90-degree edges.

Enhance your monument production workflow →

CNC Engraving Machine

Multi-Axis CNC Monument Engraving Machine Adds detailed inscriptions and decorative elements to memorial stones. Works with wire-cut pieces, allows engraving before or after wire saw cutting based on design needs.

Elevate your memorial detailing capabilities →

CNC Automatic Vision Grinding Machine

Smart CNC Stone Surface Polishing Machine,Uses camera technology to automatically detect surface contours and adapt to different stone thicknesses. Ideal for polishing irregular tombstones cut by wire saws with consistent quality.

Achieve perfect finishes on complex memorial stones →

Get a Custom Solution

Transform Your Memorial Stone Production Today

Experience precision cutting with minimal waste and maximum efficiency. Our experts will customize the perfect solution for your specific needs.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Memorial Stone Fabrication Knowledge

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC Vertical Wire Saw Machine for High-Precision Cutting

LSSJ-800

This CNC wire saw machine cuts both straight lines and complex curves for memorial stones with ±1mm accuracy. Its vertical design uses 40% less floor space than horizontal machines, perfect for small workshops with limited space. Processes granite, marble, basalt, limestone, sandstone, and engineered stone into detailed tombstones, crosses, sculptures, memorial plaques, and architectural elements with smooth surfaces that require minimal polishing.

Compatible Materials & Products

Precision Cutting Across Multiple Stone Materials for Premium Memorial Products

▶ Product Demo

Granite ❯ Tombstones

Marble ❯ Crosses

Granite ❯ Monuments

Basalt ❯ Decorative Elements

|

|---|

DINOSAW CNC Vertical Wire Saw Machine Video |

▶ Product Demo

Granite ❯ Tombstones

Marble ❯ Crosses

Granite ❯ Monuments

Basalt ❯ Decorative Elements

|

|---|

DINOSAW CNC Vertical Wire Saw Machine Video |

Consult DINOSAW Material Expert →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Italian Marble Tombstone Workshop

Doubling Production Capacity While Reducing Material Waste

A family-owned memorial workshop in Carrara, Italy upgraded to our vertical diamond wire saw, achieving 15% savings in expensive marble material costs and 45% reduction in cutting time. The precision system creates complex shapes with minimal kerf width.

The space-efficient design allowed installation without facility expansion, while eliminating the need for multiple specialized tools. Production capacity doubled within three months, with higher quality finishes requiring less secondary processing.

Revolutionize your small workshop productivity →

American Memorial Design Studio

Expanding Design Capabilities for Premium Client Demands

A monument manufacturer in Vermont, USA implemented our vertical diamond wire saw to handle complex custom designs that traditional methods couldn't fulfill. This unlocked the ability to create intricate curved shapes previously requiring outsourcing.

The precision control system executes sophisticated designs directly from CAD files, reducing production delays by 60%. Client satisfaction increased as the company delivered custom monuments with previously impossible design elements.

Master premium monument production →

Brazilian Granite Monument Specialist

Achieving Intricate Natural Designs with Modern Efficiency

A premium memorial producer in Espírito Santo, Brazil transformed their workflow with our vertical diamond wire saw. It enables precision cutting of complex organic patterns and regional motifs while maintaining their renowned artistic quality.

The technology reduced labor costs by 35% and cut material waste in half. Production time for specialized curved elements decreased from 3 days to 7 hours, allowing more specialized orders and expansion of their premium product line.

Master premium monument production →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | LSSJ-1900-9H |

|---|---|---|

flywheel | mm | 2x900 |

Max.cutting height | mm | 800mm |

Trimming diameter range | mm | 1600~1900mm |

Wire diameter | mm | 4~8.8 |

Main motor power | kw | 11 |

Overall dimensions | m | 3.69x1.9x3.6 |

Contact DINOSAW technical team for details →

Discover why DINOSAW diamond wire saw is the ideal solution for stone memorial profiling.

Big Cutting Power, Small Footprint

Space-Saving Design

Vertical structure reduces footprint by over 50% compared to horizontal configurations.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Inqury for Details →

Space-Saving Design

Vertical structure reduces footprint by over 50% compared to horizontal configurations.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Integrated Frame Design

Easy installation - simply secure the machine body to begin operation.

Remote Operation

OTA technology for remote updates and maintenance support.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Bridge Saw Machine

Precision Stone Cutting Bridge Saw for Tombstone Pre-cuts stone slabs to required thickness and dimensions before wire saw shaping. Provides stable platform for accurate straight cuts with 90-degree edges.

Enhance your monument production workflow →

CNC Engraving Machine

Multi-Axis CNC Monument Engraving Machine Adds detailed inscriptions and decorative elements to memorial stones. Works with wire-cut pieces, allows engraving before or after wire saw cutting based on design needs.

Elevate your memorial detailing capabilities →

CNC Automatic Vision Grinding Machine

Smart CNC Stone Surface Polishing Machine,Uses camera technology to automatically detect surface contours and adapt to different stone thicknesses. Ideal for polishing irregular tombstones cut by wire saws with consistent quality.

Achieve perfect finishes on complex memorial stones →

Get a Custom Solution →

FAQs

Common Questions About Vertical Diamond Wire Saw Machines

What types of stone can this diamond wire saw machine cut?

What types of stone can this diamond wire saw machine cut?

How does a vertical wire saw differ from horizontal models?

How does a vertical wire saw differ from horizontal models?

What is the maximum cutting capacity of this machine?

What is the maximum cutting capacity of this machine?

How long do diamond wires typically last?

How long do diamond wires typically last?

Need more assistance? Contact DINOSAW →

Global Leader in Industrial

Machinery & Diamond Tools

Manufacturing

Certifications & Standards

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

75+

Countries Served Worldwide

20+

Industry machinery expertise

Transform Your Memorial Stone Production Today

Expand Your Memorial Stone Fabrication Knowledge

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Memorial Stone Fabrication Knowledge

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?