Introduction: Choosing the Right Rock Cutting Saw

Selecting the best rock cutting saw directly impacts productivity and costs in mining and factory operations. Whether you’re cutting granite in quarries or shaping marble slabs in factories, the wrong equipment can lead to wasted materials, downtime, and safety risks. This guide helps you:

Compare key features of quarry saws and industrial stone cutters

Match machines to your specific materials and workloads

Calculate long-term savings from reduced maintenance and higher efficiency

Need Immediate Help?

If you already know your requirements or want expert advice on the best rock cutting saw for your project:

Explore Our Products: Browse mining saws and factory stone cutters here

Get a Custom Quote: Contact us or chat online now for free consultation and pricing

Which is the best rock cutting saw for you?

The optimal equipment for stone cutting varies significantly based on the application context. Rather than a one-size-fits-all approach, professional stoneworkers select specialized tools for specific operational environments.

Quick Reference Guide for Stone Cutting Solutions

Application | Stone Type | Processing Need | Recommended Equipment |

|---|---|---|---|

Quarrying | Marble | High-bench extraction | |

Quarrying | Granite | Low-bench extraction | |

Quarrying | Sandstone | Soft stone extraction | |

Fabrication | Granite | Block to slab conversion | |

Fabrication | Marble & luxury stone | Block to slab conversion | Multi-Wire Saw (20% higher yield) |

Fabrication | All stones | Complex shape cutting | |

Fabrication | All stones | Cylindrical/spherical objects | |

Fabrication | All stones | Finished products | |

Fabrication | Marble & ceramics | Inlays & detailed patterns |

Quarrying Operations

Marble Extraction (High-Bench Quarrying)

For high-value marble extraction, quarries employ high-bench quarrying methods to maximize block size and integrity. This approach preserves the stone's commercial value by producing larger, more cohesive blocks suitable for premium applications.

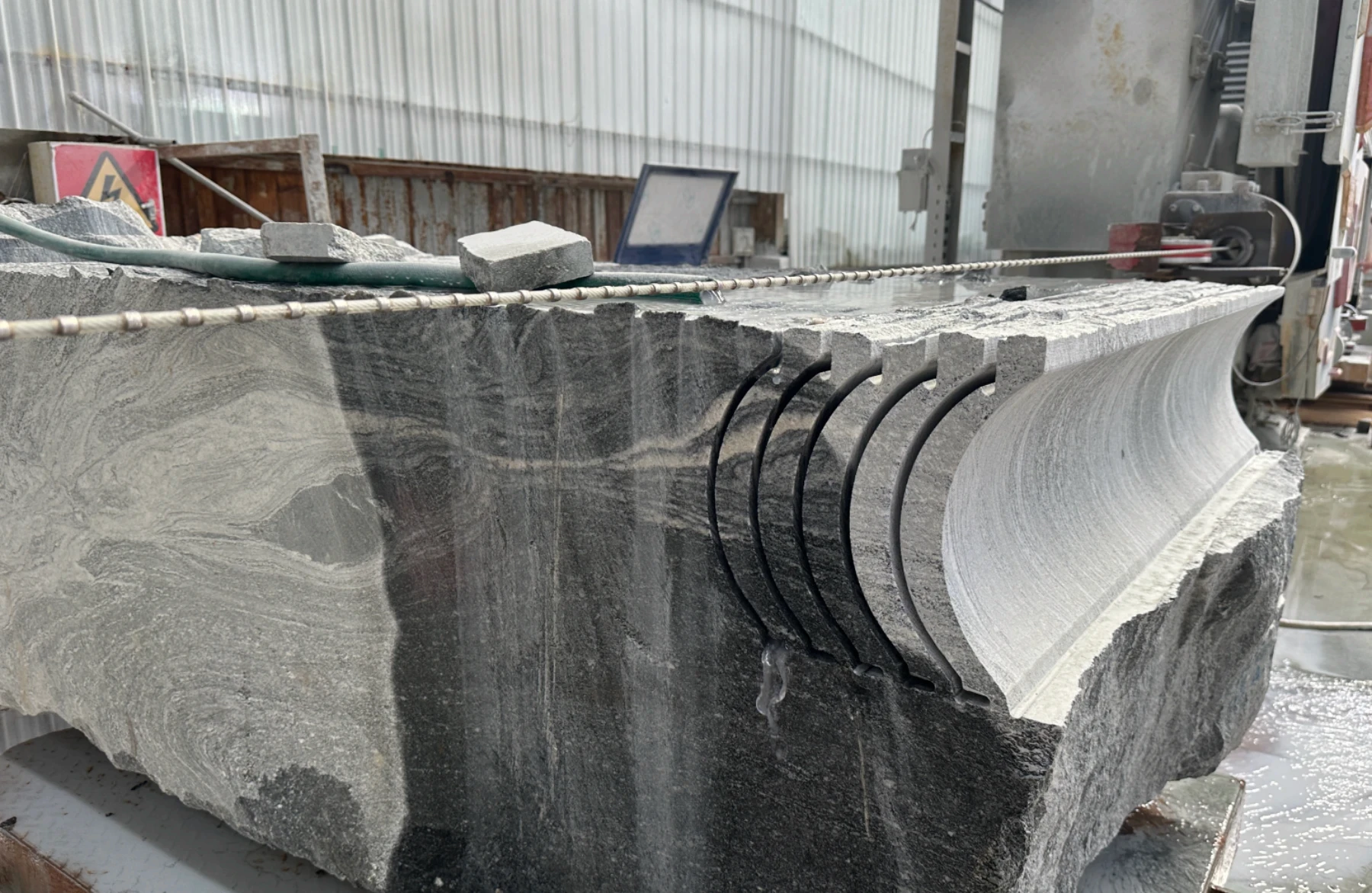

Diamond Wire Saw Machines: The primary tool for marble extraction, delivering clean cuts with minimal material loss. Modern CNC-controlled wire saws achieve cutting speeds of 4-8 m²/hour , preserving the block's structural integrity.

Quarry Chainsaws: Complementary to wire saws, these machines excel at vertical cutting with depths up to 3400mm. With cutting speeds of 0.5-4 meters/hour and power ratings of 30-50kW, they create precise initial cuts that facilitate subsequent extraction phases.

DTH (Down-The-Hole) Drilling Equipment: Essential for creating access points for wire insertion. The holes serve as channels for diamond wire threading, enabling the execution of primary separation cuts in marble formations.

Granite Extraction (Low-Bench Quarrying)

For granite and other moderate-value stone types, quarries implement low-bench extraction methods. This approach prioritizes operational efficiency and cost-effectiveness through smaller bench heights and block dimensions.

Double-Blade Saw Machines: These systems excel in efficient preliminary cutting, with parallel blades creating simultaneous cuts that significantly reduce extraction time. Cutting depths range from 400-600mm with blade diameters of 600-1200mm.

Diamond Wire Saws (for undercutting): Used specifically for horizontal base cuts after vertical face cutting. This "undercutting" technique separates the block from the quarry floor, completing the extraction process with minimal waste.

Sandstone and Soft Stone Extraction

For softer stone varieties like sandstone, specialized dry-cutting systems offer the most efficient extraction solution.

Sandstone Cutting Machines: Purpose-built for soft stone with dry-cutting capabilities, these machines eliminate water requirements while maintaining cutting depths of up to 520mm. Their high-speed cutting (15-20 m²/hour) and simplified transportation make them ideal for soft stone quarrying operations.

Stone Fabrication Workshop

Block-to-Slab Processing

The transformation of raw blocks into marketable slabs requires specialized equipment based on material properties and desired output quality.

Multi-Blade Stone Block Cutters: Preferred for granite processing, these systems employ multiple parallel blades (up to 80 blades simultaneously) to convert blocks into uniform slabs.

Traditional Gangsaws: Historically used for marble slab production.

Multi-Wire Saws: The newest technology for premium stone block cutting. For high-value marble and luxury stone, multi-wire systems deliver superior results with significantly reduced kerf width (0.5mm) and material waste. This technology increases yield by >20% compared to traditional gangsaws, making it the recommended choice for valuable materials like rare marble, onyx, and premium decorative stone.

Custom Shape Fabrication

For specialized architectural elements and custom designs, precision-controlled systems offer unmatched versatility.

CNC Mono-Wire Saw Machines: Essential for creating complex shapes from stone blocks. These systems excel at cutting tombstones, sculptures, furniture components, and custom architectural elements with variable cutting trajectories and 3D path capabilities. With precision of ±1mm, they transform raw blocks into finished art pieces with minimal material waste.

Cylindrical and Spherical Components

For railings, columns, spheres, fountains, and decorative moldings, specialized profiling equipment delivers the required dimensional accuracy.

Stone Lathes (Stone Profile Machines): These specialized machines combine rotational movement with cutting tools to create perfectly symmetrical objects. Modern CNC stone lathes can produce perfect stone spheres in 30-40 minutes, making them ideal for manufacturing balusters, columns, fountains, and decorative elements.

Finished Product Fabrication

For countertops, vanities, and finished consumer products, precision cutting and edge processing are essential.

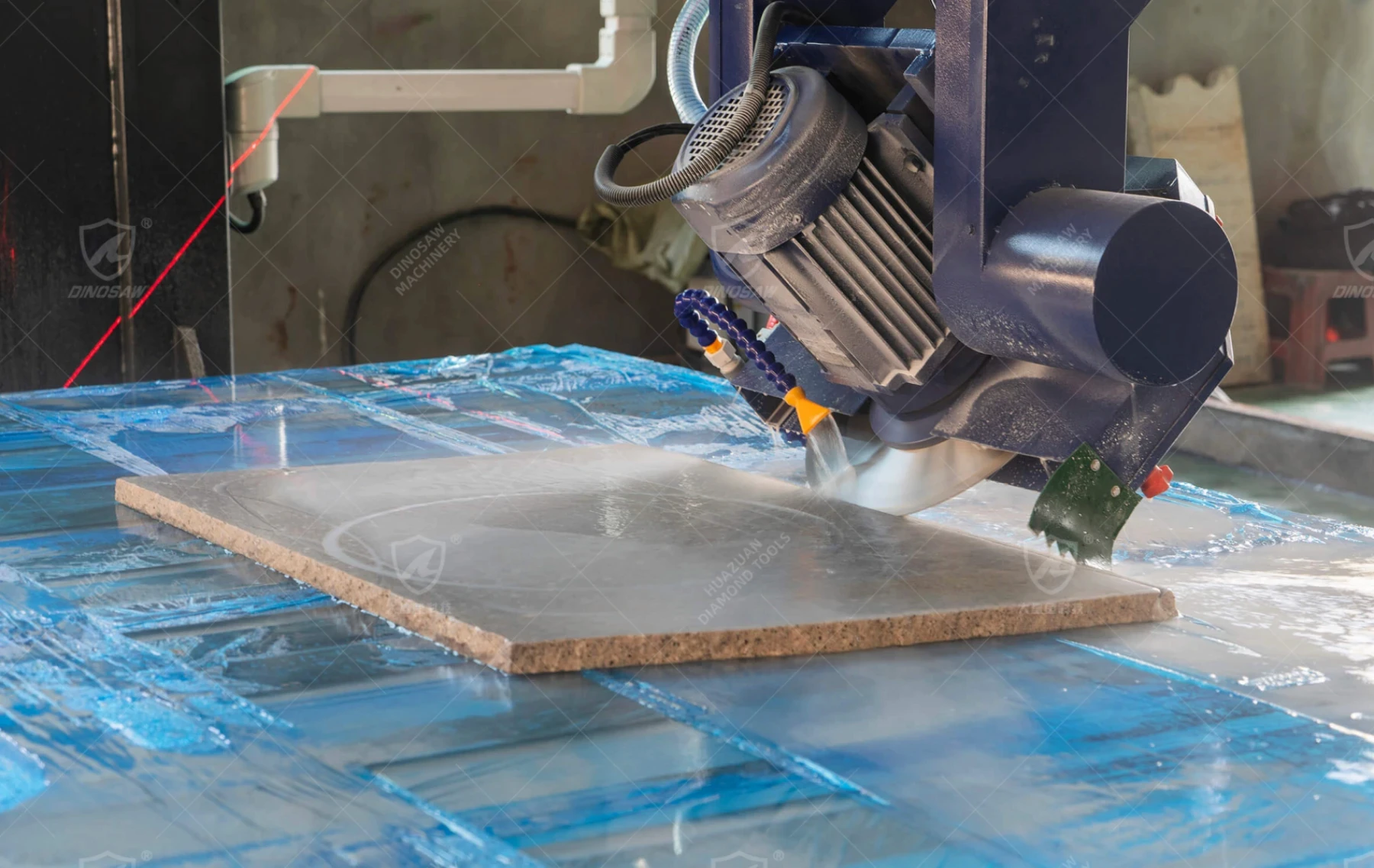

CNC Bridge Saws: The workhorse of stone fabrication shops. Available in 3-axis, 4-axis, and 5-axis configurations, these systems achieve cutting accuracy of ±0.05mm for precise countertop, sink, vanity, and architectural component fabrication. Advanced models with DDX control systems automate measurement and processing, eliminating human error.

Precision Inlay and Mosaic Work

For detailed pattern cutting and intricate designs, waterjet technology offers unmatched precision.

Waterjet Cutting Machines: Ideal for ceramic tile, marble inlays, and detailed mosaic work. Using high-pressure water with abrasive additives, these systems cut complex patterns without thermal effects. Their precision and ability to cut thin materials make them perfect for decorative applications and premium design elements.

Small-Scale Operations

For budget-conscious small fabricators focusing on basic cutting and 45° edge processing, simplified solutions offer cost-effective performance.

Manual Stone Cutting Machines: Offering excellent value for small workshops, these machines handle basic slab cutting and 45° beveling with modest investments. While lacking automation, they deliver acceptable precision for standard applications, making them an ideal entry point for small-scale stone processing operations.

Mining Applications: High-Efficiency Rock Cutting

Quarry Scenarios and Requirements

Mining Operations

Used for rock excavation (open-pit or underground mining), tunnel construction, and ore segmentation. Must handle high-hardness rocks (e.g., granite, basalt) and complex geological conditions.

Key Needs

High cutting strength, impact resistance, stability for continuous operation, and safety features.

Quarry Rock Cutter Types and Technical Parameters

Equipment Type | Technical Features | Applicable Scenarios |

|---|---|---|

With belt drive, chrome-plated guide pillars, ensures stable, safe, and high-precision cutting. Power: 118–138kW, cutting depth 850–2150mm | Marble/granite block mining | |

Diamond bead wire with 360° rotation, suitable for irregular rock masses. Motor power: up to 110kW | Complex terrain mining, tunnel cutting, underwater cutting | |

Compact design, compatible with rails or excavators, efficient for medium-hardness stones. Cutting depth: up to 3400mm, power: 30-50kW, cutting speed: 0.5-4 m/h | Medium hardness stone quarrying (marble, limestone, sandstone), narrow spaces, auxiliary trimming | |

Dual-blade synchronous cutting, high precision, dry-cutting system. Max. cutting depth: 520mm | Sandstone quarrying and block cutting | |

Down-the-hole drilling technology, efficient for hard stone extraction, often used with wire saws for block separation. Drilling diameter: 90-120mm | Granite, marble and limestone quarrying, preparatory work for wire sawing, vertical and horizontal drilling applications |

Key Purchasing Criteria

Power & Torque: Match motor power to rock hardness (≥30kW recommended for granite).

Efficiency: Focus on cutting speed (33–45 m/s optimal) and feed rate.

Safety: Prioritize emergency brakes, protective covers, and auto-shutdown mechanisms.

Maintenance Costs: Opt for modular designs and easily replaceable blades (e.g., DINOSAW Mining Saw with blade life up to 2,000 hours).

Stone Factory Rock Cutting Saw Purchasing Considerations

Factory Scenarios and Requirements

Processing Stages: Block cutting, slab shaping, and sculpting. Requires precision, low material waste, dust control, and versatility (e.g., angled or curved cuts).

Common Equipment Types and Technical Parameters

Equipment Type | Technical Features | Applicable Scenarios |

|---|---|---|

High-efficiency multi-blade cutting for mass production. Max blade diameter: 3200mm. | Standard stone slab cutting from raw blocks (e.g., marble, granite). | |

Narrow kerf width (0.5 mm), high-speed cutting at 40 m/s. Increases productivity by 20% compared to traditional gangsaw. | Cutting high-value stone blocks (luxury stone) and ultra-thin slabs (thickness: 3-15mm). | |

Processes blocks up to 5×2.4m with ±1mm precision. Features hydraulic tensioning system, PLC-controlled automatic cutting. | Block edge correction, vertical cutting, and block splitting. Increases block value by up to 40% through precise squaring. | |

CNC system for complex shapes. Cutting accuracy: ±1 mm, efficiency: 2.5 m²/h. Single wire system with flexible cutting trajectory. | Landscape stone, curbs, tombstones, and irregular sculptures. Ideal for custom-shaped architectural elements. | |

Multi-axis cutting, adjustable thickness (max 700mm), rotatable worktable (3.2m × 2.0m). Cutting accuracy ±0.05mm with DDX control system. | Slabs, sinks, countertops, and custom architectural components. Ideal for fabrication shops producing finished stone products. | |

High-pressure water + abrasives, no thermal deformation. Precision: ±0.1 mm. 5-axis movement for complex 3D shapes. | Intricate engravings, thin slabs (≤10mm), and artistic designs. Ideal for detailed pattern cutting without heat effects. | |

Diamond blade + water cooling, 45° angle adjustment. Portable design for flexible on-site operations. | On-site installation adjustments, small repairs, and edge polishing. Ideal for custom modifications and quick fixes. |

Key Purchasing Criteria

Precision: Choose CNC models with repeat positioning accuracy ≤0.05mm.

Eco-Friendliness: Opt for water recycling systems (≥90% efficiency).

Smart Features: IoT monitoring and auto-tool changers boost productivity.

Blade Compatibility: Universal blade interfaces reduce costs (e.g., supports φ350–600mm blades).

Rock Cutting Equipment Supplier Selection

Selecting the right supplier for your stone cutting equipment is as crucial as choosing the equipment itself. A reliable partner ensures not just quality machinery, but also comprehensive support throughout the equipment's lifecycle. This guide will help you evaluate potential suppliers and understand why DINOSAW stands out in the industry.

Supplier Evaluation Checklist

Technical Support & Service✓ Response time guarantees ✓ Availability of local technicians and spare parts ✓ Regular preventive maintenance programs ✓ Remote diagnostics and troubleshooting capabilities | Training & Knowledge Transfer✓ Comprehensive operator training ✓ Maintenance staff certification programs ✓ Documentation quality (operations, maintenance, troubleshooting)✓ Video libraries and online knowledge bases |

|---|---|

Warranty & After-Sales✓ Warranty terms ✓ Spare parts availability guarantee ✓ Software updates and upgrades policy ✓ Extended warranty and service contract options | Compliance & Safety✓ Regulatory certifications (CE, ISO, etc.) ✓ Safety features (emergency stops, guards) ✓ Noise and dust emission standards compliance ✓ Environmental impact (water recycling, energy efficiency) |

Why Choose DINOSAW as Your Stone Equipment Supplier

DINOSAW delivers end-to-end excellence in stone cutting solutions with a focus on quality, innovation, and responsive support:

Advanced R&D: 20+ years industry experience. Our team develops intelligent, automated equipment. Dedicated mechanical, electrical, and software specialists focus on innovations that reduce costs and extend equipment life.

Custom Solutions: From modified standard machines to completely bespoke systems tailored to your specific stone types and workspace requirements

Quality Manufacturing: Equipment produced in ISO 9001 and CE-certified facilities using premium components with rigorous quality control

Global Reach: Our specialized logistics ensure safe, timely delivery to 75+ countries worldwide with comprehensive customs support

Expert Installation: Factory-trained technicians handle complete setup, ensuring optimal performance from day one

Rapid Response: 30-minute initial feedback and 4-hour on-site service guarantee minimizes costly downtime

Preventive Maintenance: Customized maintenance programs prevent breakdowns through proactive service interventions

Specialized Training: Application-specific training ensures operators achieve optimal cutting efficiency with any material

Choose DINOSAW for 20+ years industry expertise, global service across 4 continents, CE-certified equipment, and a team dedicated to your success.

DINOSAW welcomes machinery agents and distributors to our network. Benefits include exclusive territories, competitive pricing, marketing support, and technical training. Contact us about partnership opportunities.

Ready to Optimize Your Stone Cutting Operations? Inqury to Discover how DINOSAW's expertise can transform your productivity and material yield

Frequently Asked Questions About Rock Cutting Saws

Our technical experts have compiled answers to the most common questions specifically about rock cutting saws to help you make informed decisions for your particular application.

Which rock cutting saw is best for a small quarry operation?

A: For small quarry operations, we recommend starting with a Diamond Double-Blade Saw for its versatility and lower initial investment. These machines offer cutting depths of 400-600mm and are suitable for both marble and granite extraction in low to medium bench heights. They provide a good balance between cutting precision (±3mm) and operational costs.

For expanding operations, consider adding a Diamond Wire Saw for larger blocks and complex cuts. DINOSAW's quarry-focused models include dust-resistant features (IP65+ rated) and simplified maintenance procedures specifically designed for small operational teams .

What saw specifications should I look for when cutting high-value marble blocks?

A: When cutting high-value marble blocks, focus on machines that minimize material waste and preserve block integrity. Key specifications include:

• Narrow kerf width: Select wire saws with 0.5-8mm kerf width to maximize valuable material recovery

• Precision control: Look for CNC-guided systems with positioning accuracy of ±1mm or better

• Vibration management: Choose equipment with balanced cutting action and vibration dampening to prevent micro-fractures in delicate marble

• Variable speed control: Ensure the saw offers 10-40m/s wire speed adjustment for adapting to different marble hardness and crystalline structures

• Water delivery system: Verify uniform cooling coverage to prevent thermal stress and color changes in premium marble

DINOSAW's Multi-Wire Saw specifically designed for luxury stone offers these features plus real-time tension monitoring to prevent wire breakage during valuable block cutting.

How do I choose between a bridge saw and a CNC wire saw for my fabrication shop?

A: Your choice should be guided by your primary product offerings:

Choose a CNC Bridge Saw if:

• You primarily produce countertops, vanities, and standard architectural elements

• Precision finishing and edge details are critical (±0.05mm accuracy)

• You need faster production times for standard thickness materials

• Your work involves 45° edges, sink cutouts, and similar standardized fabrication

Choose a CNC Wire Saw if:

• You regularly create custom shapes, sculptures, and 3D objects

• Material yield is a primary concern (especially with expensive stone)

• Your projects include curved surfaces that cannot be achieved with blade cutting

• You work with ultra-thin slabs (3-15mm) that might crack under blade pressure

Many successful fabrication shops eventually invest in both technologies, starting with the saw that best matches their initial market focus. DINOSAW offers hybrid options that combine wire and blade capabilities for workshops seeking maximum versatility.Maintenance and Operational Questions

How can I extend the life of diamond saw blades when cutting hard granite?

A: To maximize diamond blade life when cutting hard granite:

1. Proper break-in procedure: Cut soft material (limestone or concrete) for the first 50m² to gradually expose diamond particles

2. Optimal rotation speed: Maintain 35-45m/s peripheral speed - too fast accelerates wear, too slow reduces cutting efficiency

3. Consistent water cooling: Ensure 15-20 liters/minute of clean water to prevent overheating and thermal damage

4. Appropriate feed rate: Use 0.5-1.5m/hour feed rate for granite depending on hardness - listen to the motor sound to detect overloading

5. Regular blade dressing: When cutting efficiency decreases, make 2-3 cuts in abrasive material like brick to re-expose diamonds

6. Inspect mounting flanges: Ensure flanges are flat, clean, and properly tightened to prevent wobbling

DINOSAW's granite-specific blades with optimized diamond concentration and bond hardness can achieve 30-40% longer life than standard blades when following these practices .

What's causing my rock cutting saw to make excessive noise and vibration?

A: Excessive noise and vibration in rock cutting saws typically stem from six common causes, each with specific solutions:

1. Blade/wire issues:

• Inspect for worn segments, cracks, or deformations

• Check if tension is uniform (for wire saws)

• Verify blade is appropriate for the material being cut

2. Mounting problems:

• Ensure flanges are flat, clean, and properly torqued (40-60 Nm typically)

• Verify blade hole diameter matches arbor exactly

• Check for debris between flanges and blade

3. Bearing wear:

• Test for arbor play (should be less than 0.05mm)

• Listen for characteristic bearing whine

• Replace bearings in pairs if wear is detected

4. Misalignment:

• Verify blade/wire is perpendicular to travel direction

• Ensure guide rails are parallel and level

• Check motor and arbor alignment

5. Material feed issues:

• Confirm consistent feed pressure

• Ensure material is securely clamped

• Verify feed speed matches material hardness

6. Structural resonance:

• Inspect machine foundation and mounting

• Check for loose components amplifying vibration

• Verify machine is level and properly anchored

DINOSAW's remote diagnostic service can analyze vibration patterns to pinpoint exact causes before they lead to equipment damage or dangerous operating conditions.