The Importance of Efficient Precious Stone Cutting

In the stone mining and processing industry, precious stone cutting machines are essential for enhancing productivity, precision, and cost-efficiency. Whether it’s luxury stone, agate, or other high-value gemstones, the ability to cut these materials accurately and efficiently is a game-changer. Among the various cutting technologies, diamond wire saw machines have emerged as the go-to solution for both mining operations and stone processing factories.

As the demand for luxury stone craft grows—particularly in high-end applications like countertops, sculptures, and flooring—the need for precise cutting equipment becomes even more crucial. Traditional methods, like bridge saws and gang saws, while still in use, often come with limitations in terms of cutting precision and material wastage. This is where diamond wire saw machines (also referred to as wire saw machines) step in, offering a significant advantage in terms of cutting quality, speed, and cost-efficiency.

By utilizing diamond wire saw cutting machines, quarry operators and stone fabricators can achieve remarkable results with high precision and minimal material loss. In this article, we will explore the benefits of these machines, compare them to traditional cutting methods, and explain why they are a worthy investment for modern stone cutting operations.

What is a Precious Stone Cutting Machine?

Exploring Diamond Wire Saw Machines for Stone Cutting

A diamond wire saw machine is an advanced tool used for cutting through tough materials, such as luxury stone and gemstones. Unlike traditional saws that use rigid blades or discs, wire saw machines use a thin, flexible diamond-coated wire to cut through materials. The wire is moved along the material using a continuous loop, with the diamond abrasives on the wire providing the cutting power.

The core difference between a diamond wire saw and other traditional cutting machines, such as bridge saws or gang saws, lies in the method of cutting and the efficiency with which these machines perform. While bridge saws are excellent for making straight cuts, they can be less effective when it comes to cutting intricate shapes or angles in hard stones like luxury stone. Additionally, the wider cutting blades of traditional machines can lead to greater material wastage.

A diamond wire saw machine offers several key advantages:

Flexibility: The wire can make intricate, precise cuts, making it ideal for complex shapes and designs.

Thin Cutting Gap: The cutting gap is significantly smaller than that of traditional machines, reducing material waste.

Higher Efficiency: The machine can operate continuously, allowing for faster cutting speeds compared to older methods.

Precision: The accuracy of diamond wire saw machines is superior, achieving cutting tolerances of less than 1mm, which is crucial for high-value materials.

Overall, the diamond wire saw machine is a versatile and efficient solution for cutting a wide range of precious stones, from large slabs to intricate carvings.

Key Benefits of Using Precious Stone Cutting Machines

In the world of luxury stone and gemstone cutting, precision and efficiency are essential. Whether it's luxury stone used in high-end applications like countertops and sculptures, or agate and other high-value gemstones, the cutting method plays a critical role in determining the final product’s quality and profitability. Here’s why diamond wire saw machines have become the go-to solution for cutting these materials:

High Precision with Minimal Waste

One of the standout features of diamond wire saw machines is their remarkable precision. The machines can cut with tolerances as fine as 1mm, a crucial factor when working with luxury stones and gemstones. Traditional cutting methods, like gang saws and bridge saws, often result in larger cutting gaps, leading to more material loss. In comparison, diamond wire saws create a significantly thinner cut (typically around 0.5mm), ensuring that more of the precious material is retained, thus maximizing yield.

Faster Cutting Speed and Increased Efficiency

In addition to precision, diamond wire saw machines offer significantly faster cutting speeds than traditional equipment. This is particularly important in both quarrying and stone processing, where time efficiency translates directly to increased productivity and lower operating costs. The continuous cutting action of the wire also reduces the downtime associated with blade or disc replacements in traditional systems, further enhancing the overall efficiency of operations.

Versatility and Ability to Cut Complex Shapes

Unlike traditional cutting machines that are typically limited to making straight cuts, diamond wire saws excel in cutting luxury stones into intricate shapes and curves. This capability is particularly important for creating custom pieces for luxury stone craft, such as countertops, sculptures, and decorative features. The flexibility to make both straight and complex cuts opens up new possibilities for designers and fabricators working with valuable materials.

Durability and Cost-Effectiveness

Diamond wire saw machines, particularly those designed by DINOSAW such as the KSSJ-M/G series and the DSY-XJ3011 multi-wire saw machine, are built for durability and long-term performance. Their robust design and reliable cutting performance ensure that operators can rely on them for high-volume operations with minimal maintenance. While the initial investment in a diamond wire saw machine may be higher than traditional machines, the long-term savings from reduced material waste and faster cutting times often outweigh the upfront costs.

How Diamond Wire Saw Machines Work for Cutting Precious Stones

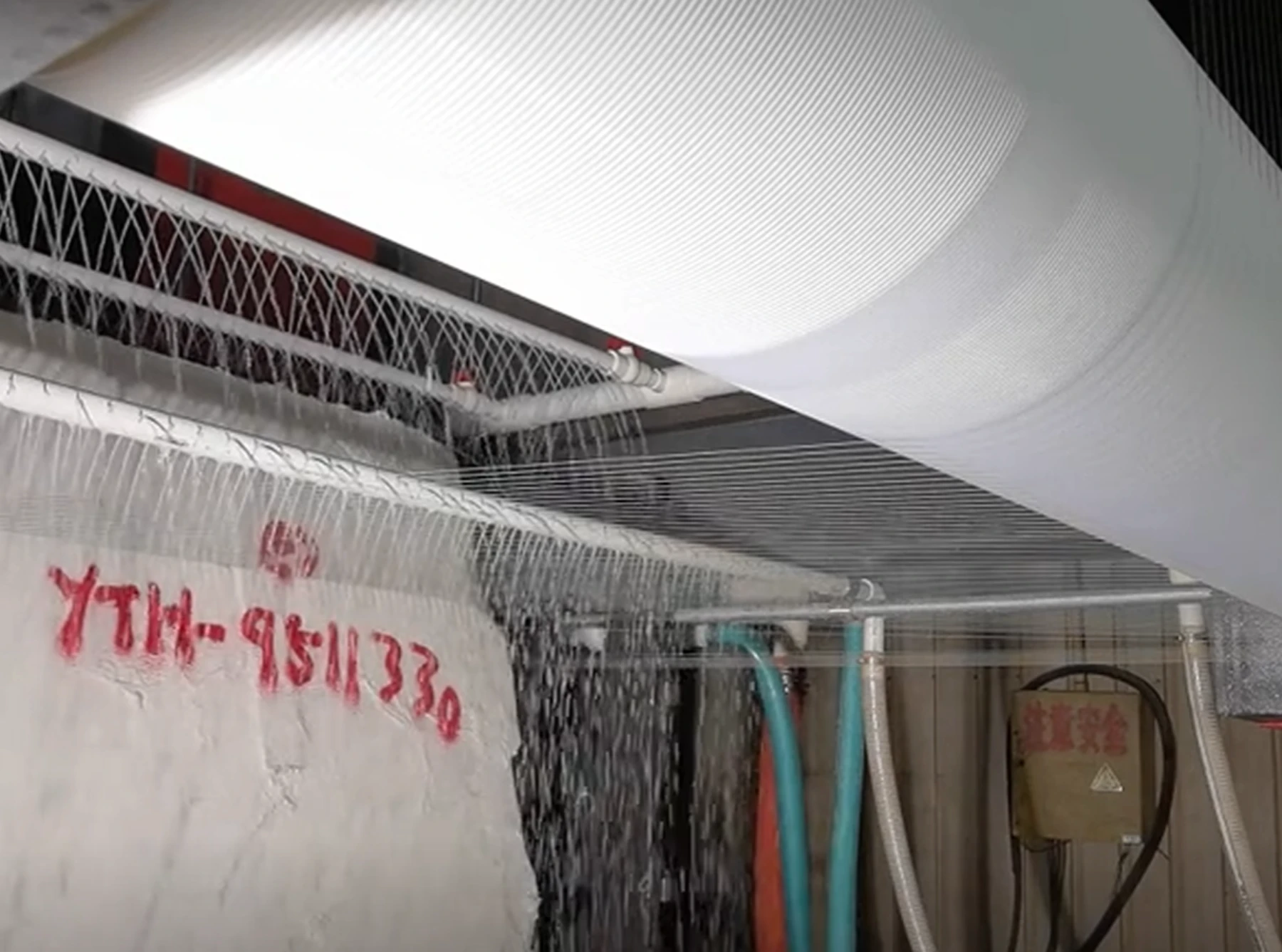

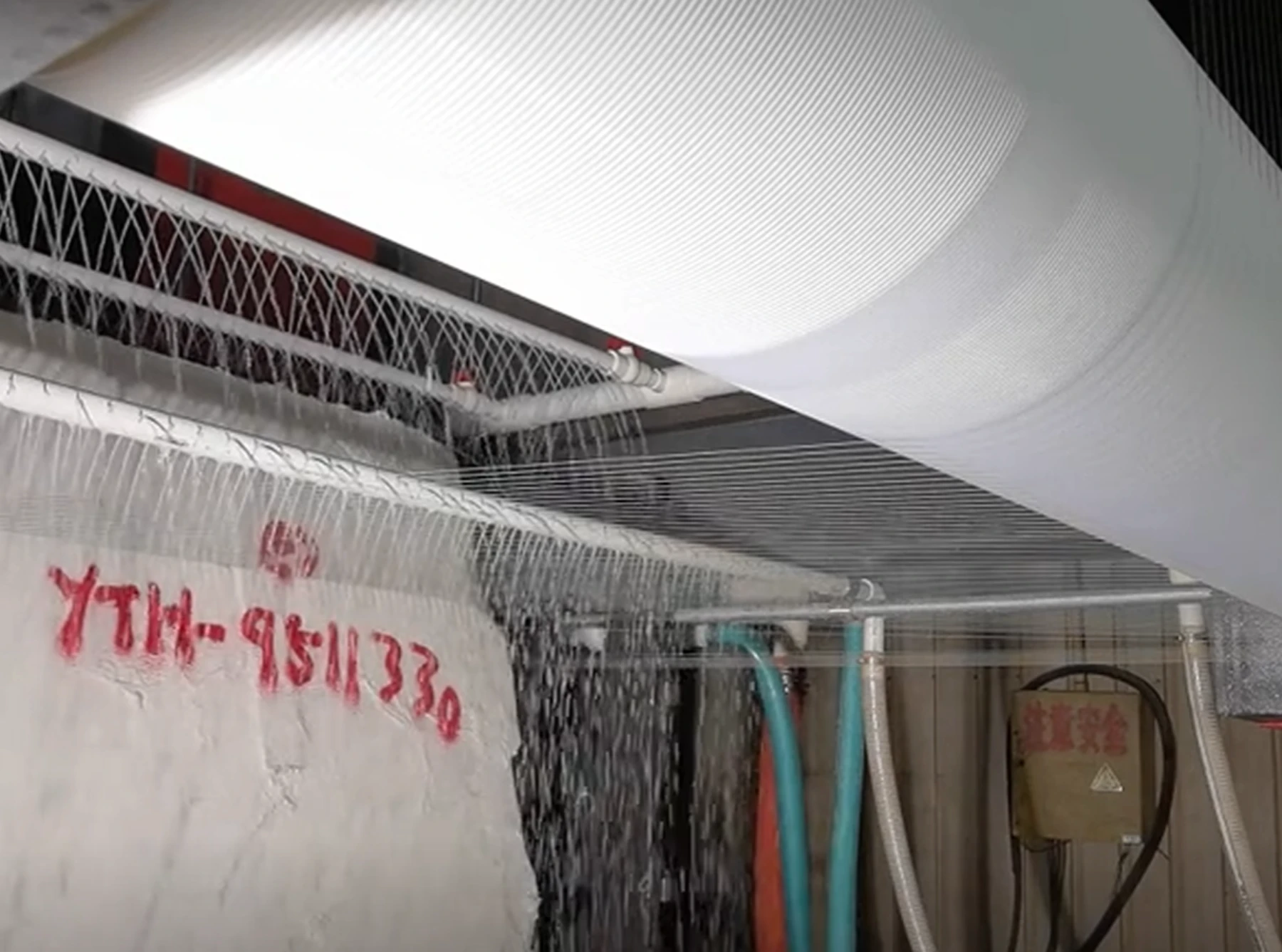

Diamond wire saw machines are widely used in both mining operations and stone cutting factories. Their versatility makes them suitable for a variety of applications, including stone extraction, slab cutting, and luxury stone crafting. Let’s take a closer look at how these machines excel in these two key areas:

Quarrying Operations: Efficient Stone Extraction

In mining operations, diamond wire saw machines are used to extract large blocks of luxury stone or agate with minimal damage. Traditional methods like chain saws or explosive techniques can result in cracks or breakages, causing significant material loss. In contrast, a diamond wire saw machine offers a much cleaner extraction process, preserving the quality of the material and reducing the need for rework.

For example, the KSSJ-M/G series of diamond wire saw machines are specifically designed for mining operations. With a motor power ranging from 36-110 kW, these machines can handle large blocks of stone, making them perfect for quarrying luxury stone and other precious materials.

Stone Cutting Operations: High-Precision Slab Cutting

In stone processing factories, diamond wire saw machines are invaluable for cutting slabs from large stone blocks. Unlike gang saws, which often leave rough edges, diamond wire saw machines produce smoother cuts with less than 1mm tolerance, making them ideal for producing high-quality slabs for use in luxury stone craft applications like countertops, flooring, and wall panels.

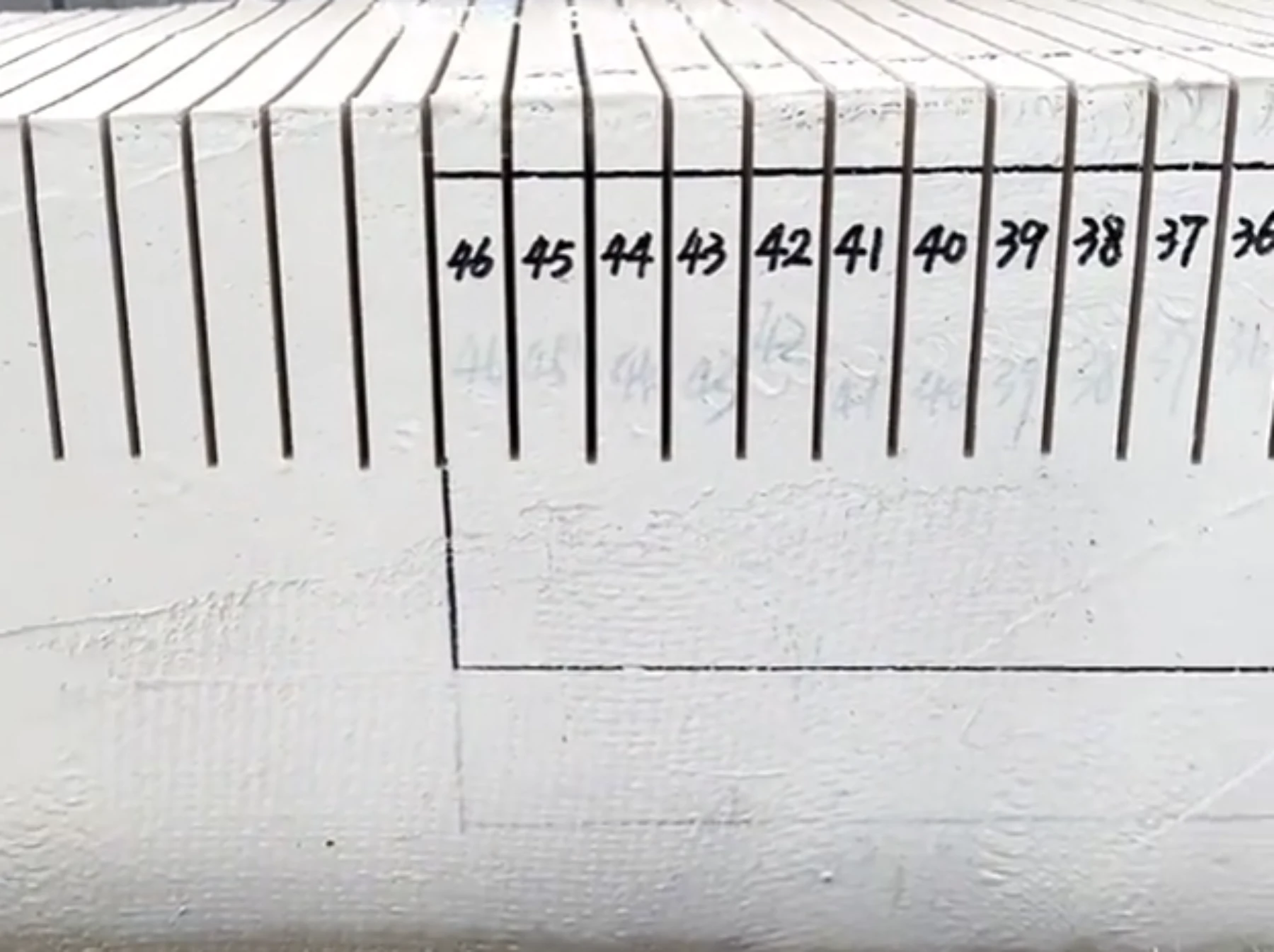

The DSY-XJ3011 multi-wire saw machine is perfect for cutting slabs of luxury stone in bulk. It can achieve cutting tolerances as low as 0.5mm, making it ideal for factories looking to increase efficiency and reduce material loss.

Applications of Diamond Wire Saw Machines in Mining and Stone Cutting

Diamond wire saw machines are transforming the way precious stones and luxury stones are extracted and processed in the mining and stone cutting industries. With their unmatched precision, flexibility, and efficiency, they provide solutions for a variety of cutting needs, from quarrying to stone processing. Below are some key applications where these machines shine:

Efficient Quarrying of Precious Stones

In the mining and quarrying sectors, diamond wire saw machines are increasingly being used to extract luxury stones like marble, granite, onyx, and gemstones such as agate. Unlike traditional methods, such as using chainsaws or drilling, wire saws enable a smoother extraction process with minimal impact on the surrounding environment. The wire’s continuous motion allows operators to make precise cuts along the stone layers, effectively splitting large stone blocks with reduced risk of breakage.

For luxury stone quarries, where maintaining the integrity of the stone is critical, diamond wire saws provide a level of control that traditional methods simply can’t match. This results in higher-quality blocks, better yields, and ultimately, higher profit margins.

Cutting Large Slabs and Panels for Stone Fabrication

Once precious stones are extracted, the next step is often cutting them into usable slabs or panels for various applications, including countertops, flooring, and wall panels. Multi-wire saws, like the DSY-XJ3011, are particularly beneficial for cutting luxury stone slabs efficiently. The ability to cut multiple slabs at once reduces the time and energy required for processing, improving production efficiency and reducing costs.

Moreover, with multi-wire saws, operators can achieve consistent thickness across all slabs, ensuring uniformity in product quality. This is especially important when producing slabs that require high precision for luxury stone applications, where even slight thickness variations can lead to costly errors.

Custom Cuts for Luxury Stone Crafting

In stone crafting and stone sculpture, diamond wire saw machines are invaluable tools for creating intricate designs and complex shapes. Unlike traditional saws that are limited to straight cuts, diamond wire saws provide the flexibility to perform 360-degree cutting with minimal material waste. This is especially useful for crafting custom stone features such as sculptures, landscape stones, and artistic stone designs that require a high degree of accuracy.

Whether you're producing finely detailed stone art or designing high-end luxury stone features for interior decoration, a diamond wire saw cutting machine can help achieve precise and delicate cuts that elevate the beauty of the final product.

Precise Cutting for High-Value Gemstones

In the realm of gemstone cutting, the precision required is far higher than in typical stone cutting operations. Diamond wire saw machines designed for gemstone cutting, such as the YXSJ-2500/3000/3500-16pro series, can cut gemstones with tolerances as tight as 1mm, ensuring that even the most delicate stones are handled with care. For precious materials like agate, jade, and other high-value gemstones, these machines provide an efficient way to maximize material yield while maintaining the stone’s integrity.

Recommended Diamond Wire Saw Machines for Luxury Stone Cutting

After understanding the advantages and applications of diamond wire saw machines in precious stone cutting, it’s time to explore the best equipment for your stone quarrying and cutting needs. DINOSAW offers a range of advanced diamond wire saw machines that can revolutionize the way you work with luxury stones.

1. KSSJ-M/G Series – Diamond Wire Saw Machines for Quarrying

The KSSJ-M/G Series is designed specifically for quarry mining operations where precision and power are crucial. With a main motor power ranging from 36 to 110 kW, this machine can handle the toughest and largest stone blocks with ease. Its ability to cut through luxury stones like granite, marble, and onyx ensures that quarry owners can maximize yield while minimizing waste and maintaining the quality of extracted material.

Key Features:

High Motor Power: With a robust motor power range, the KSSJ-M/G series excels in heavy-duty applications.

Precision and Flexibility: Achieves smooth, precise cuts with minimal environmental impact, ideal for luxury stone quarrying.

Enhanced Productivity: Improves overall productivity by reducing downtime and increasing cutting efficiency.

For more details, visit the KSSJ-M/G series product page: KSSJ-M/G Series

2. DSY-XJ3011 – Multi-Wire Saw for Large-Scale Stone Slab Cutting

The DSY-XJ3011 is an advanced multi-wire saw machine designed for stone slab cutting. With the ability to cut multiple slabs simultaneously, this machine is ideal for luxury stone processing factories looking to improve efficiency and maximize output. It is especially beneficial for industries that require precision cutting with narrow gaps between slabs (0.5mm), such as granite, marble, and other high-value stones.

Key Features:

Efficient Cutting: Cuts multiple slabs at once, dramatically reducing cutting time.

Precision: Achieves extremely narrow saw gaps (as small as 0.5mm) for uniform slab thickness.

Versatility: Capable of processing various luxury stones, including marble, granite, and onyx.

For more information, check the DSY-XJ3011 product page: DSY-XJ3011 Multi-Wire Saw

3. YXSJ Series – CNC Diamond Wire Saw Cutting Machines for Custom Stone Cutting

The YXSJ-2500/3000/3500-16pro Series CNC diamond wire saw cutting machines are perfect for custom stone cutting and luxury stone crafting. Whether you’re working with precious gemstones or intricate stone sculptures, these machines offer the precision needed to achieve high-end results. With tolerances as tight as 1mm and 360° cutting capabilities, these machines can deliver superior craftsmanship for both small-scale and large-scale stone cutting projects.

Key Features:

Precision Cutting: Capable of achieving cuts with an error margin of less than 1mm.

360° Cutting: Offers complete flexibility for custom stone designs and sculptures.

CNC Technology: Facilitates high-precision operations for luxury stone crafting.

Learn more about the YXSJ Series and its features: YXSJ Series CNC Cutting Machines

How to Get Started with Precious Stone Cutting Machines

Now that you have an in-depth understanding of how diamond wire saw machines can benefit your luxury stone cutting operations, the next step is to make the investment that will transform your business.

At DINOSAW, we offer comprehensive support throughout your entire journey with diamond wire saw machines. From on-site factory inspections to customized machine production, we ensure that each step is tailored to meet your needs. Our services include:

Custom Machine Production: Tailored to your specific requirements for luxury stone cutting.

Shipping & Installation: Efficient and secure delivery, followed by expert installation.

After-Sales Support: We provide ongoing maintenance and technical support to ensure optimal machine performance.

Comprehensive Training: Access to a vast library of video tutorials and documentation to help you understand machine operation, installation, and maintenance.

Customer Support: For any questions, visit our FAQ and Support sections, or contact us directly via WhatsApp or email for real-time assistance.

We are committed to delivering full-cycle management to help you maximize efficiency and ensure a smooth, hassle-free experience with your precious stone cutting machines.

Contact Us Now: Request a Quote or Consultation

Conclusion: Maximize Your Quarry and Stone Processing Efficiency

Upgrading your stone cutting operations with diamond wire saw machines is a decision that can bring long-term benefits in terms of cutting precision, cost savings, and product quality. By investing in the right equipment, such as DINOSAW's range of diamond wire saw machines, you can enhance your luxury stone processing operations and position your business for growth in a competitive industry.

With advanced technology and tailored support, DINOSAW is the partner you need to take your quarrying and stone processing operations to the next level. Contact us today to learn more and make your investment in the future of luxury stone cutting.

FAQs

What types of stones can be cut with a diamond wire saw machine?

Diamond wire saw machines are ideal for cutting luxury stones like granite, marble, onyx, as well as precious stones such as agate, gemstones, and jade.

How much power do diamond wire saw machines consume?

The power consumption of diamond wire saw machines depends on the model and application, but machines like the KSSJ-M/G Series typically have motors ranging from 36kW to 110kW for maximum efficiency in mining and quarrying.

How do diamond wire saws compare to traditional saws like bridge saws?

Diamond wire saws offer several advantages over traditional saws, including narrower cutting gaps, better precision, faster cutting speeds, and reduced stone wastage, which is particularly important for valuable stones.

Can I use diamond wire saw machines for both mining and processing?

Yes, diamond wire saw machines are highly versatile and can be used for both stone quarrying and stone processing tasks. Models like the YXSJ-2500/3000/3500-16pro are perfect for custom stone cutting and luxury stone crafting.

How do I get started with purchasing a diamond wire saw machine?

Contact DINOSAW to discuss your specific needs. Our team will guide you through the selection process and provide a customized quote based on your stone cutting requirements.