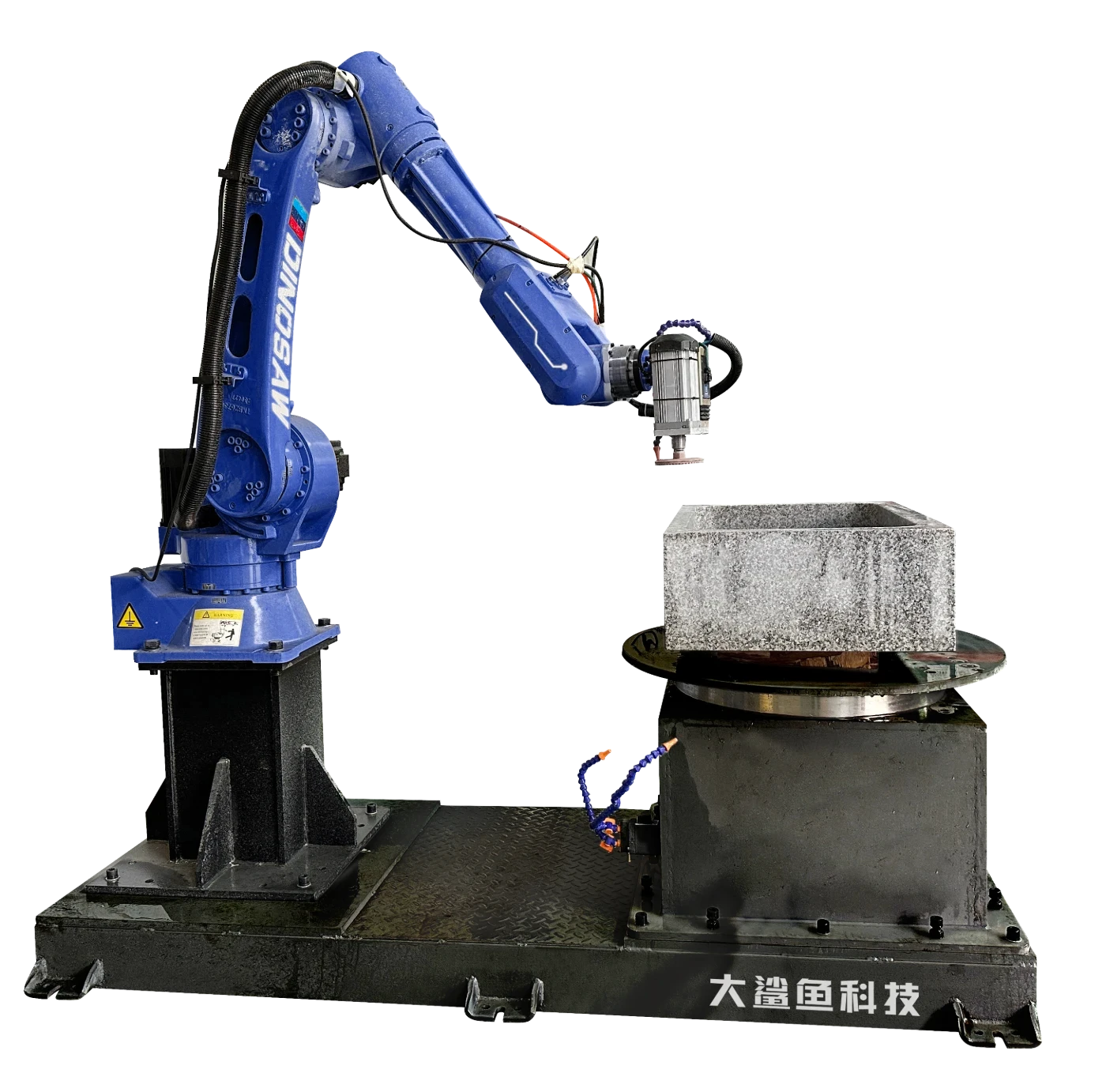

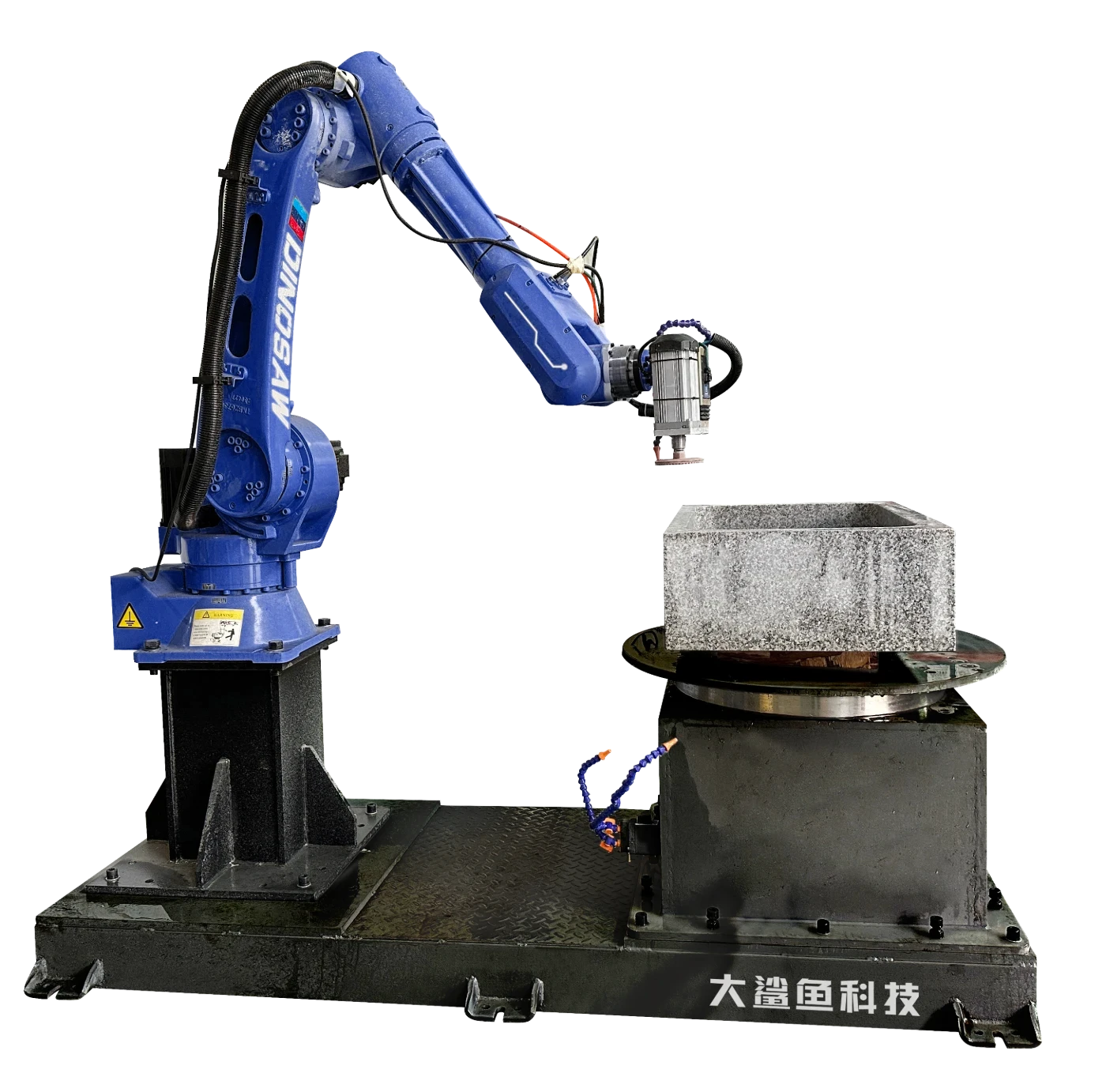

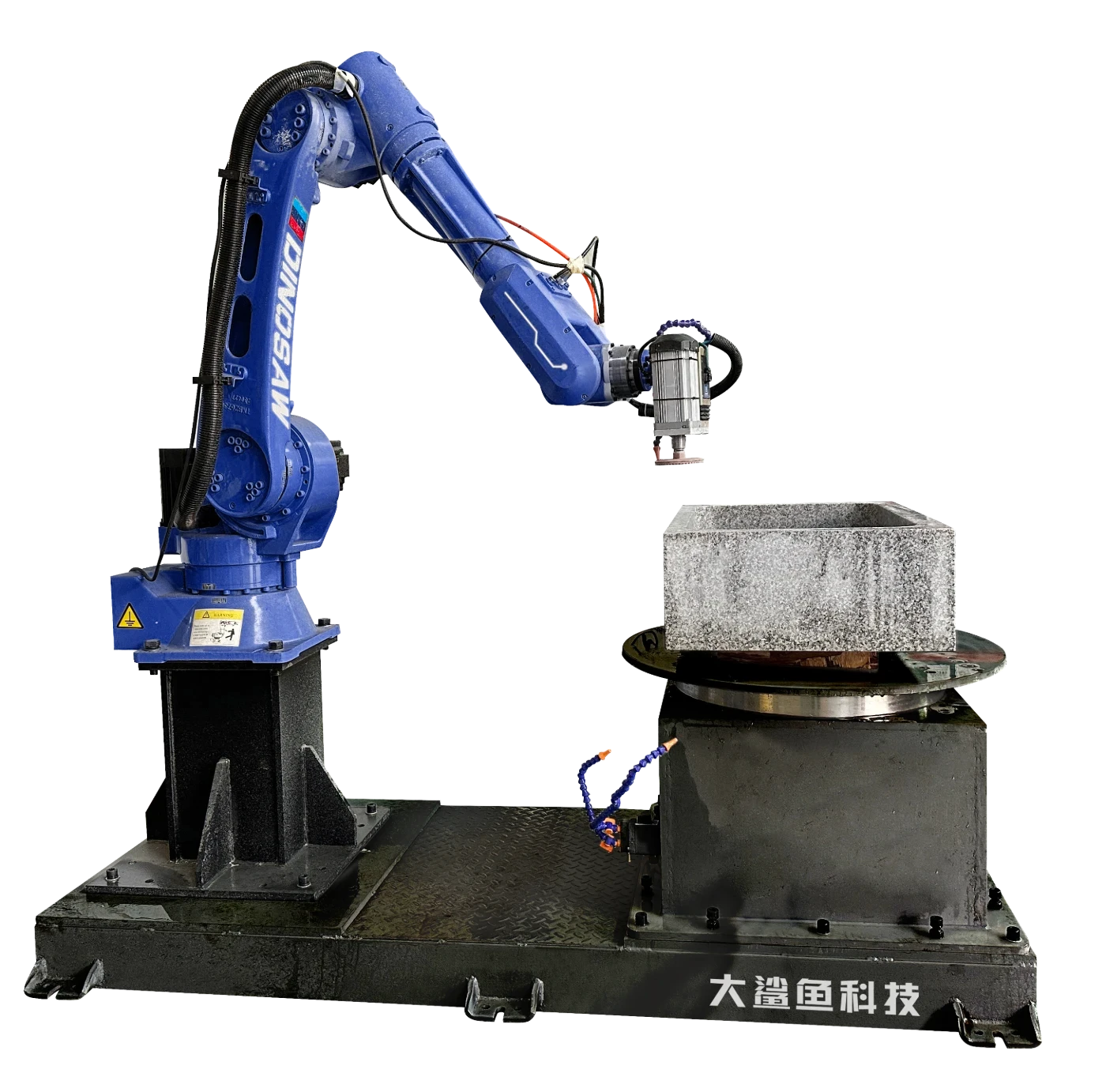

CNC ATC Grinding & Polishing Machine

DINO-SKS DP-01

DINOSAW CNC Stone polishing machine combines vision recognition and automatic tool changing for efficient processing. The camera captures any shape, creating optimal grinding paths for perfect finishing. Multi-head system automatically progresses from coarse to fine polishing in one setup. For materials including granite, marble, engineered stone, quartzite, sandstone, limestone, onyx, ceramic slabs, metal and composites, this machine excels at polishing thick monuments, memorial stones and irregular stone shapes.

Compatible Materials & Products

▶ Product Demo

Granite & Marble > Monuments & Tombstones

Irregular Stone Shapes > Custom Elements

Thick Stone > Sculptural Works

Quartz & Engineered Stone > Specialty Surfaces

▶ Product Demo

Granite & Marble > Monuments & Tombstones

Irregular Stone Shapes > Custom Elements

Thick Stone > Sculptural Works

Quartz & Engineered Stone > Specialty Surfaces

Consult DINOSAW Material Expert →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Master irregular countertops now →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Master irregular countertops now →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Master irregular countertops now →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Master irregular countertops now →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Specs and options

Specifications customizable upon request.

Model | Unit | DINO-SKS DP-01 |

|---|---|---|

Max. working length | mm | 3000 |

Max. working width | mm | 2000/2800 |

Max. working height | mm | 1000 |

Main motor power | KW | 7.5 |

Overall dimensions (L x W x H) | mm | 5500x4000x2850 |

Weight | T | 4 |

Contact DINOSAW technical team for details →

Precision stone grinding technology designed for monuments, irregular forms & thick materials

Advanced CNC Stone Polishing for Challenging Materials & Shapes

Visual Recognition

Camera maps work area, one-click selection for automatic optimal grinding path generation

Auto Tool Changing

Switches polishing tools from coarse to fine without manual work

Built-in Process Library

One-click parameter setup for various stone tasks. Simple operation for all processing needs

Inqury for Details →

Visual Recognition

Camera maps work area, one-click selection for automatic optimal grinding path generation

Auto Tool Changing

Switches polishing tools from coarse to fine without manual work

Built-in Process Library

One-click parameter setup for various stone tasks. Simple operation for all processing needs

Inqury for Details →

High Gloss Single-Pass

Achieves 114 gloss level in one operation. No multiple polishing passes needed

Edge Recognition

Maps irregular stone edges precisely, eliminating empty area processing for maximum efficiency

Multi-Height Processing

Auto Z-axis adjustment for materials with different heights in one setup

1000mm Z-axis Capacity

Processes thick monuments standard polishers cannot handle

Live Monitoring

Tracks grinding process with instant parameter adjustments. Built-in alarm detects abnormalities

Adaptive Grinding

Adjusts for stone hardness variations, ensuring uniform finish across all material types

FAQs

Common Questions About DINOSAW Automatic Tools Changing CNC Polishing Machines

How does this machine compare to manual polishing and mono-head automatic polishing machines?

How does this machine compare to manual polishing and mono-head automatic polishing machines?

How does the visual recognition system work for irregular stone shapes?

How does the visual recognition system work for irregular stone shapes?

What types of materials can this ATC CNC polishing machine process?

What types of materials can this ATC CNC polishing machine process?

What applications and finished products are ideal for this CNC polishing machine?

What applications and finished products are ideal for this CNC polishing machine?

Can this CNC polisher process multiple different pieces in a single setup?

Can this CNC polisher process multiple different pieces in a single setup?

What is the advantage of the visual system for polishing irregular shapes?

What is the advantage of the visual system for polishing irregular shapes?

Need more assistance? Click to contact DINOSAW →

Certifications & Standards

Global Leader in Industrial Machinery & Diamond Tools Manufacturing

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Carving & Engraving Machine

Engraves monuments and decorative panels with multiple spindles for higher efficiency. Creates precise lettering, portraits and decorative features on granite, marble and engineered stone. Pairs perfectly with the CNC ATC Grinding & Polishing Machine for complete monument production.

Enhance your monument engraving now →

Diamond Wire Saw CNC Stone Cutting Machine

Cuts irregular shaped monuments with precise contour control. Shapes custom tombstones before finishing with the CNC ATC Grinding & Polishing Machine. Processes thick granite and marble with minimal waste and accurate dimensional control.

Design custom monuments now →

Stone Polishing Robot with KUKA & Sprut

Polishes irregular stone edges with 6-axis robotic precision. Handles edge details standard machines cannot reach. Works alongside the CNC ATC Grinding & Polishing Machine - robot focuses on edges while main machine handles surfaces.

DINOSAW Stone Polishing Robot processing complex irregular stone edges and contours

Get a Custom Solution

Ready to Transform Your Monument & Irregular Stone Processing?

DINOSAW's CNC ATC Grinding & Polishing Machine excels with monuments, thick stones, and irregular shapes. Contact our specialists today

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Polishing Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC ATC Grinding & Polishing Machine

DINO-SKS DP-01

DINOSAW CNC Stone polishing machine combines vision recognition and automatic tool changing for efficient processing. The camera captures any shape, creating optimal grinding paths for perfect finishing. Multi-head system automatically progresses from coarse to fine polishing in one setup. For materials including granite, marble, engineered stone, quartzite, sandstone, limestone, onyx, ceramic slabs, metal and composites, this machine excels at polishing thick monuments, memorial stones and irregular stone shapes.

Compatible Materials & Products

▶ Product Demo

Granite & Marble > Monuments & Tombstones

Irregular Stone Shapes > Custom Elements

Thick Stone > Sculptural Works

Quartz & Engineered Stone > Specialty Surfaces

▶ Product Demo

Granite & Marble > Monuments & Tombstones

Irregular Stone Shapes > Custom Elements

Thick Stone > Sculptural Works

Quartz & Engineered Stone > Specialty Surfaces

Consult DINOSAW Material Expert →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Batch Monument Polishing

High-Volume Tombstone Production with Single Setup

A monument company processed only 1 headstone at a time. With DINOSAW's CNC Stone Polishing Machine, they now process 6-12 granite tombstones simultaneously. The system detects stone positions, applies optimal parameters and changes tools automatically.

Boost your monument production today →

Custom Irregular Countertops

Precision Edge-to-Edge Polishing for Designer Surfaces

A kitchen fabricator needed extensive manual work for irregular-shaped countertops. DINOSAW's visual system captured exact outlines and created precise grinding paths. This eliminated empty area processing, removed manual finishing, and delivered consistent quality.

Create multi-material masterpieces →

Custom Memorial Projects

Multi-Material Memorial Masterpieces in Single Operation

A memorial studio combined granite, marble and engineered stone of different thicknesses. Using DINOSAW CNC Stone Polishing Machine, they processed all components in one setup.

The system identified each piece through visual recognition, adjusted parameters by material type, and reduced completion time from 14 to 4 days.

Create multi-material masterpieces →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | DINO-SKS DP-01 |

|---|---|---|

Max. working length | mm | 3000 |

Max. working width | mm | 2000/2800 |

Max. working height | mm | 1000 |

Main motor power | KW | 7.5 |

Overall dimensions (L x W x H) | mm | 5500x4000x2850 |

Weight | T | 4 |

Contact DINOSAW technical team for details →

Precision stone grinding technology designed for monuments, irregular forms & thick materials

Advanced CNC Stone Polishing for Challenging Materials & Shapes

Visual Recognition

Camera maps work area, one-click selection for automatic optimal grinding path generation

Auto Tool Changing

Switches polishing tools from coarse to fine without manual work

Built-in Process Library

One-click parameter setup for various stone tasks. Simple operation for all processing needs

Inqury for Details →

Visual Recognition

Camera maps work area, one-click selection for automatic optimal grinding path generation

Auto Tool Changing

Switches polishing tools from coarse to fine without manual work

Built-in Process Library

One-click parameter setup for various stone tasks. Simple operation for all processing needs

Inqury for Details →

High Gloss Single-Pass

Achieves 114 gloss level in one operation. No multiple polishing passes needed

Edge Recognition

Maps irregular stone edges precisely, eliminating empty area processing for maximum efficiency

Multi-Height Processing

Auto Z-axis adjustment for materials with different heights in one setup

1000mm Z-axis Capacity

Processes thick monuments standard polishers cannot handle

Live Monitoring

Tracks grinding process with instant parameter adjustments. Built-in alarm detects abnormalities

Adaptive Grinding

Adjusts for stone hardness variations, ensuring uniform finish across all material types

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Carving & Engraving Machine

Engraves monuments and decorative panels with multiple spindles for higher efficiency. Creates precise lettering, portraits and decorative features on granite, marble and engineered stone. Pairs perfectly with the CNC ATC Grinding & Polishing Machine for complete monument production.

Enhance your monument engraving now →

Diamond Wire Saw CNC Stone Cutting Machine

Cuts irregular shaped monuments with precise contour control. Shapes custom tombstones before finishing with the CNC ATC Grinding & Polishing Machine. Processes thick granite and marble with minimal waste and accurate dimensional control.

Design custom monuments now →

Stone Polishing Robot with KUKA & Sprut

Polishes irregular stone edges with 6-axis robotic precision. Handles edge details standard machines cannot reach. Works alongside the CNC ATC Grinding & Polishing Machine - robot focuses on edges while main machine handles surfaces.

DINOSAW Stone Polishing Robot processing complex irregular stone edges and contours

Get a Custom Solution →

FAQs

Common Questions About DINOSAW Automatic Tools Changing CNC Polishing Machines

How does this machine compare to manual polishing and mono-head automatic polishing machines?

How does this machine compare to manual polishing and mono-head automatic polishing machines?

How does the visual recognition system work for irregular stone shapes?

How does the visual recognition system work for irregular stone shapes?

What types of materials can this ATC CNC polishing machine process?

What types of materials can this ATC CNC polishing machine process?

What applications and finished products are ideal for this CNC polishing machine?

What applications and finished products are ideal for this CNC polishing machine?

Need more assistance? Contact DINOSAW →

Global Leader in Industrial

Machinery & Diamond Tools

Manufacturing

Certifications & Standards

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

75+

Countries Served Worldwide

20+

Industry machinery expertise

Ready to Transform Your Monument & Irregular Stone Processing?

Master Stone Polishing: Expert Insights & Technical Resources

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Polishing Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?