Last Updated:

2025-01-15

Last Updated:

2025-01-15

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Professional Stone Quarrying Equipment

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Last Updated:

2025-04-15

Professional Stone Quarrying Equipment

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Last Updated:

2025-04-15

Last Updated:

2025-04-15

Professional Stone Quarrying Equipment & Mining Machinery

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Mining And Quarrying Machinery Types

Mining And Quarrying Machinery Types

DINOSAW offers four primary categories of mining and quarrying equipment, each designed for specific extraction and processing requirements in professional stone quarrying operations:

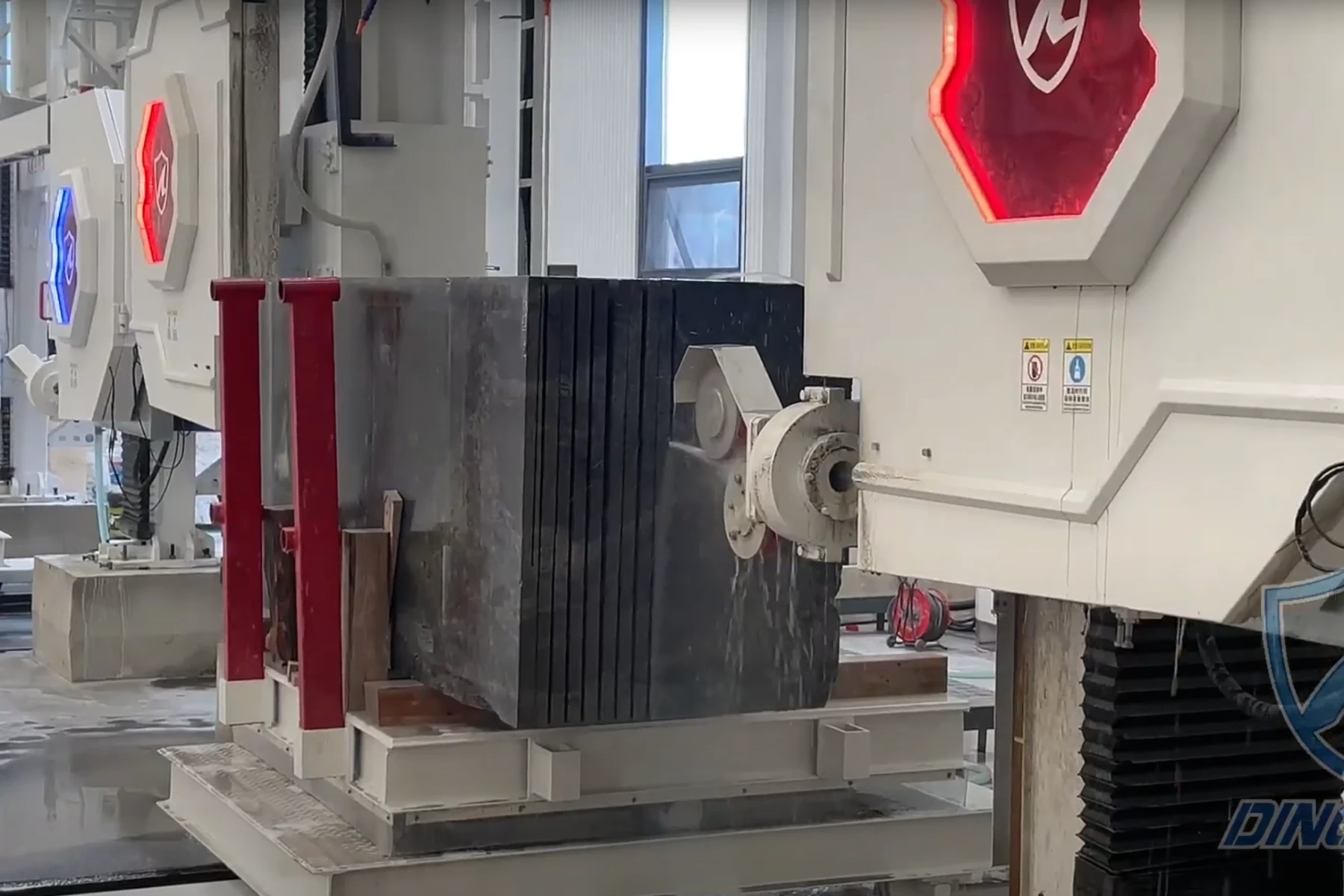

Quarry Wire Saw Machines: Advanced diamond wire technology delivers precise block separation with minimal waste, ideal for extracting large dimension stones from quarry faces.

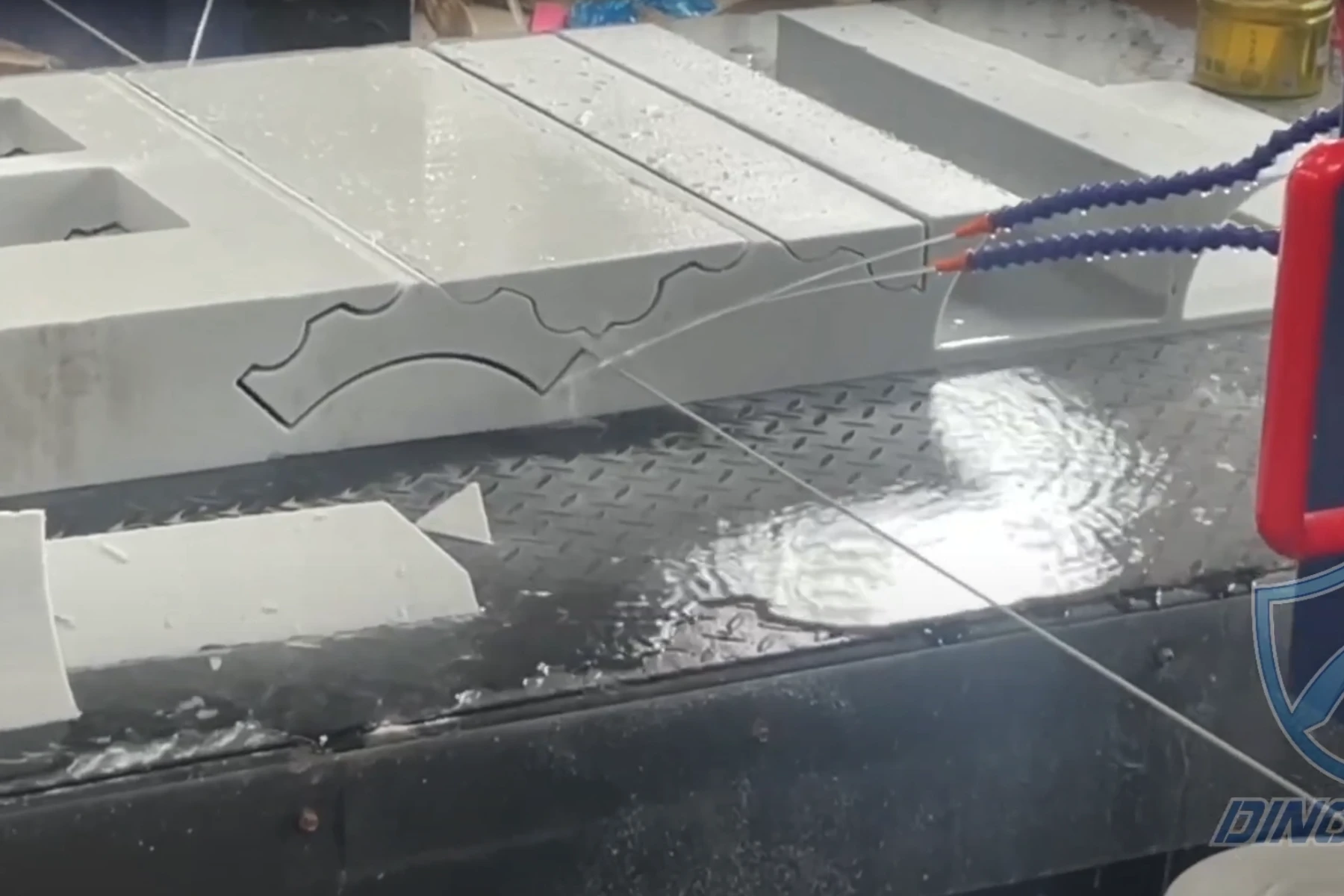

Portable Trimming Wire Saw Machines: Compact, modular design for on-site trimming and shaping, perfect for special environment operations and mobile projects requiring flexibility.

Double Blade Cutter Stone Quarrying Machines: Heavy-duty equipment for dimensional stone cutting with superior accuracy and efficient operation for processing blocks into commercial sizes.

Sandstone Cutting Machines for Quarrying: Specialized equipment designed specifically for efficient cutting of softer stone materials with maximum precision and reliability

DINOSAW offers four primary categories of mining and quarrying equipment, each designed for specific extraction and processing requirements in professional stone quarrying operations:

Quarry Wire Saw Machines: Advanced diamond wire technology delivers precise block separation with minimal waste, ideal for extracting large dimension stones from quarry faces.

Portable Trimming Wire Saw Machines: Compact, modular design for on-site trimming and shaping, perfect for special environment operations and mobile projects requiring flexibility.

Double Blade Cutter Stone Quarrying Machines: Heavy-duty equipment for dimensional stone cutting with superior accuracy and efficient operation for processing blocks into commercial sizes.

Sandstone Cutting Machines for Quarrying: Specialized equipment designed specifically for efficient cutting of softer stone materials with maximum precision and reliability

What is Mining and Quarry Machine?

What is Mining and Quarry Machine?

Mining and Quarry Machines are specialized equipment designed for extracting dimensional stone from quarries and processing raw blocks into commercial products. These machines utilize advanced technologies to efficiently separate stone blocks from natural deposits while maintaining the material's structural integrity and commercial value.

Modern quarrying equipment combines precision engineering with powerful cutting mechanisms, allowing operators to extract stone with minimal waste and environmental impact. The advanced machinery enhances extraction efficiency, reduces labor requirements, and maximizes material yield through precision cutting technology. These systems adapt to diverse quarrying environments and stone types while improving workplace safety through automated operations.

From large-scale quarry extraction to precision block cutting, modern quarrying equipment enables efficient processing of marble, granite, limestone, sandstone, basalt, quartzite, and other natural stones. DINOSAW offers comprehensive quarrying solutions that address the entire extraction workflow, significantly impacting operational productivity, product quality, and overall profitability of quarrying operations.

Mining and Quarry Machines are specialized equipment designed for extracting dimensional stone from quarries and processing raw blocks into commercial products. These machines utilize advanced technologies to efficiently separate stone blocks from natural deposits while maintaining the material's structural integrity and commercial value.

Modern quarrying equipment combines precision engineering with powerful cutting mechanisms, allowing operators to extract stone with minimal waste and environmental impact. The advanced machinery enhances extraction efficiency, reduces labor requirements, and maximizes material yield through precision cutting technology. These systems adapt to diverse quarrying environments and stone types while improving workplace safety through automated operations.

From large-scale quarry extraction to precision block cutting, modern quarrying equipment enables efficient processing of marble, granite, limestone, sandstone, basalt, quartzite, and other natural stones. DINOSAW offers comprehensive quarrying solutions that address the entire extraction workflow, significantly impacting operational productivity, product quality, and overall profitability of quarrying operations.

Quarrying Equipment Success Stories

Quarry Projects & Results

Quarrying Equipment Success Stories

Quarry Projects & Results

Granite Slab Cutting Case - CNC Wire Saw Machine Supports Egyptian Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Marble Shaped Cutting Case - CNC Wire Saw Machine Supports Brazilian Factory

Roman Column Production Case - CNC Wire Saw Machine Supports Russian

More

Quarrying Equipment Training Videos

Quarrying Equipment Training Videos

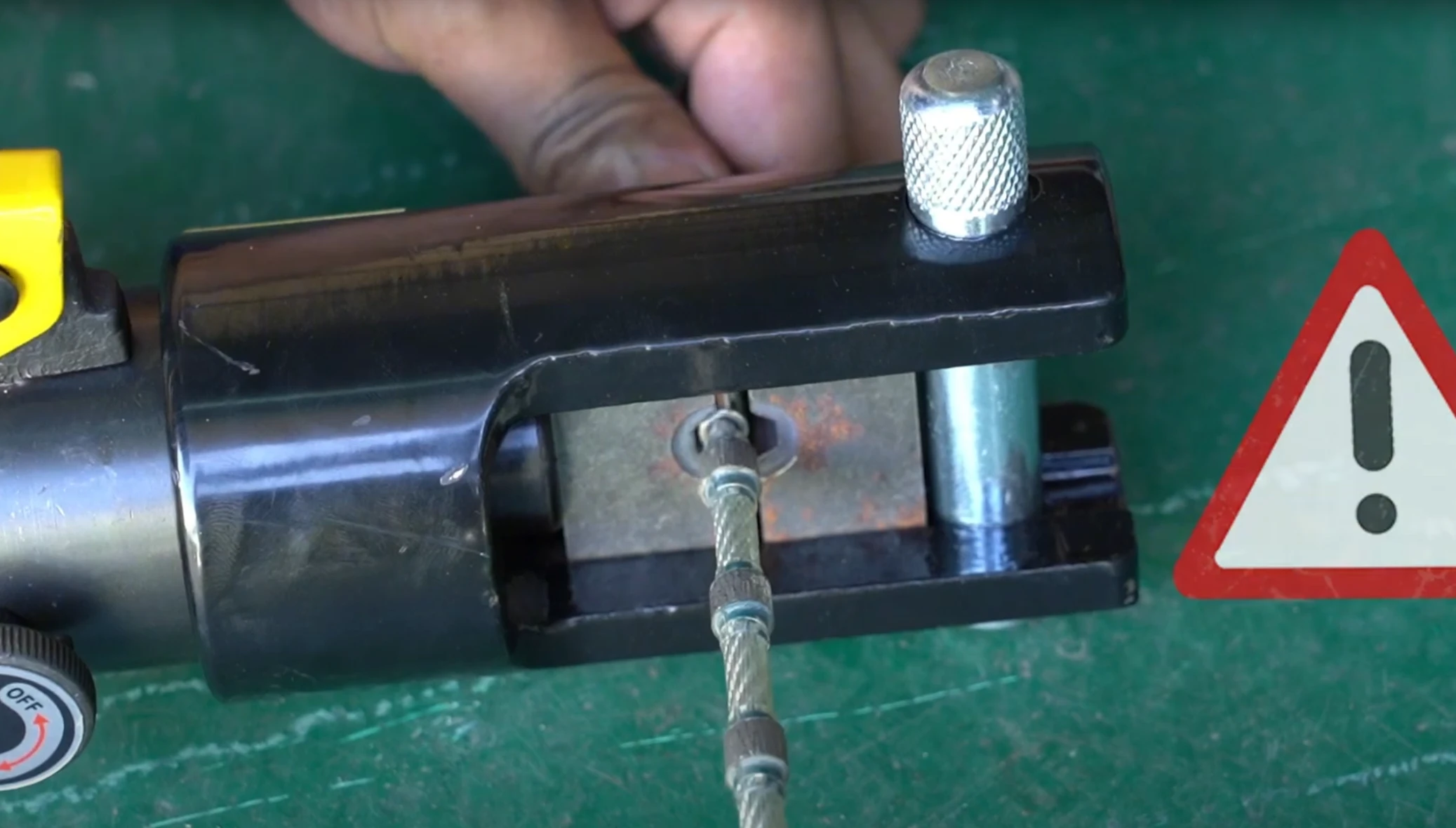

How To Operate Safely

How To Operate Safely

Quarrying Industry News

Mining Machinery Updates

Steps to Purchasing Your Ideal Grinding and Polishing Machine

Steps to Purchasing Your Ideal Grinding and Polishing Machine

Step 1: Define Your Stone Processing & Material Requirements

Start by identifying the specific stone materials you'll process (marble, granite, travertine, limestone, etc.) and determine their hardness ratings (Mohs scale 3-7). For hard materials like granite (6-7 Mohs), select machines with higher power motors and diamond abrasives. For softer stones like marble (3-4 Mohs), standard configurations work well.

Clearly define your processing needs: surface polishing for countertops and flooring, edge grinding for profiles, or specialty finishing like antiquing or leathering. Measure your typical slab dimensions and thickness (standard 2-3cm or jumbo 3+ cm) to ensure proper machine capacity.

Step 2: Evaluate Your Stone Production Volume & Workshop Capacity

Calculate your daily stone processing requirements in square meters or number of slabs. High-volume fabrication shops should invest in automatic CNC polishing machines with multiple heads for efficiency.

Small workshops handling custom stone projects will find manual polishing machines more cost-effective. Also measure your workshop space—automatic polishers require larger areas with proper water supply and drainage, while manual units need minimal operating space.

Step 3: Compare Automatic vs. Manual Stone Polishing Systems

Automatic stone polishing machines deliver consistent finishing quality across large batches with programmable CNC/PLC systems—ideal for commercial countertop production lines. They significantly reduce labor costs for high-volume operations through automated processing.

Manual stone polishers come in both surface grinding and edge grinding types, excelling in custom edge profiles, detail work, and specialized finishes like bullnose or ogee edges. Their main advantages are lower investment costs, greater flexibility for unique stone projects, and minimal space requirements. For versatile workshops, consider a combination: automatic machines for high-volume work and manual equipment for custom finishing.

Step 4: Analyze Technical Specifications for Stone Grinding Equipment

For automatic stone polishers, compare critical specifications: motor power (10-30kW total), number of polishing heads (4-12), working table dimensions (typically 3200×2000mm for standard slabs), spindle rotation speed (300-1400 RPM), and water consumption (80-150L/min). Verify the CNC/PLC system interfaces, available program storage capacity, and multi-language support for operators.

For manual stone grinding machines, evaluate motor power (1.5-3kW), tool rotation speeds (variable 1000-4500 RPM), water feed systems (gravity or pump-assisted), and weight (15-45kg for handheld units). Also compare the availability of specialized attachments for different edge profiles and surface textures.

Step 5: Calculate Total Stone Fabrication Costs & ROI

When choosing stone processing equipment, consider the total cost of ownership. This includes the initial investment (manual units cost significantly less than automatic systems), installation, consumables (diamond pads), electricity usage, water systems, and maintenance.

The main advantage of manual machines is their much lower upfront cost and faster return on investment for small workshops. Automatic systems require higher initial investment but can be cost-effective for high-volume operations through labor savings and increased productivity. Consider both your immediate budget constraints and long-term production goals when making your decision.

Step 6: Connect with DINOSAW Stone Machinery Experts

Our specialized stone equipment engineers can help evaluate your specific workshop requirements and material processing needs. We'll provide detailed machinery recommendations based on your production volume, material types, and finish quality standards. Contact us for personalized guidance on selecting the optimal granite polishing machine or marble edge grinding system for your application.

We offer comprehensive support including technical specifications, custom quotations, on-site demonstrations, delivery logistics, installation planning, operator training programs, and ongoing technical support. With 20+ years of industry expertise, we'll ensure you select the perfect stone processing solution for your fabrication business.

Step 1:

Define Your Stone Processing & Material Requirements

Start by identifying the specific stone materials you'll process (marble, granite, travertine, limestone, etc.) and determine their hardness ratings (Mohs scale 3-7). For hard materials like granite (6-7 Mohs), select machines with higher power motors and diamond abrasives. For softer stones like marble (3-4 Mohs), standard configurations work well.

Clearly define your processing needs: surface polishing for countertops and flooring, edge grinding for profiles, or specialty finishing like antiquing or leathering. Measure your typical slab dimensions and thickness (standard 2-3cm or jumbo 3+ cm) to ensure proper machine capacity.

Step 2:

Evaluate Your Stone Production Volume & Workshop Capacity

Calculate your daily stone processing requirements in square meters or number of slabs. High-volume fabrication shops should invest in automatic CNC polishing machines with multiple heads for efficiency.

Small workshops handling custom stone projects will find manual polishing machines more cost-effective. Also measure your workshop space—automatic polishers require larger areas with proper water supply and drainage, while manual units need minimal operating space.

Step 3:

Compare Automatic vs. Manual Stone Polishing Systems

Automatic stone polishing machines deliver consistent finishing quality across large batches with programmable CNC/PLC systems—ideal for commercial countertop production lines. They significantly reduce labor costs for high-volume operations through automated processing.

Manual stone polishers come in both surface grinding and edge grinding types, excelling in custom edge profiles, detail work, and specialized finishes like bullnose or ogee edges. Their main advantages are lower investment costs, greater flexibility for unique stone projects, and minimal space requirements.

For versatile workshops, consider a combination: automatic machines for high-volume work and manual equipment for custom finishing.

Step 4:

Analyze Technical Specifications for Stone Grinding Equipment

For automatic stone polishers, compare critical specifications: motor power (10-30kW total), number of polishing heads (4-12), working table dimensions (typically 3200×2000mm for standard slabs), spindle rotation speed (300-1400 RPM), and water consumption (80-150L/min). Verify the CNC/PLC system interfaces, available program storage capacity, and multi-language support for operators.

For manual stone grinding machines, evaluate motor power (1.5-3kW), tool rotation speeds (variable 1000-4500 RPM), water feed systems (gravity or pump-assisted), and weight (15-45kg for handheld units). Also compare the availability of specialized attachments for different edge profiles and surface textures.

Step 5:

Calculate Total Stone Fabrication Costs & ROI

When choosing stone processing equipment, consider the total cost of ownership. This includes the initial investment (manual units cost significantly less than automatic systems), installation, consumables (diamond pads), electricity usage, water systems, and maintenance.

The main advantage of manual machines is their much lower upfront cost and faster return on investment for small workshops. Automatic systems require higher initial investment but can be cost-effective for high-volume operations through labor savings and increased productivity. Consider both your immediate budget constraints and long-term production goals when making your decision.

Step 6:

Connect with DINOSAW Stone Machinery Experts

Our specialized stone equipment engineers can help evaluate your specific workshop requirements and material processing needs. We'll provide detailed machinery recommendations based on your production volume, material types, and finish quality standards. Contact us for personalized guidance on selecting the optimal granite polishing machine or marble edge grinding system for your application.

We offer comprehensive support including technical specifications, custom quotations, on-site demonstrations, delivery logistics, installation planning, operator training programs, and ongoing technical support. With 20+ years of industry expertise, we'll ensure you select the perfect stone processing solution for your fabrication business.

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?