Diamond Polishing Pads for Granite, Marble & Concrete

Wet/Dry Diamond Polishing Pads for sale

DINOSAW diamond polishing pads polish surfaces and edges of granite, marble, quartz, terrazzo and concrete used in countertops, tabletops, flooring and decorative elements. Available in wet, dry and hybrid options. Offered in 3" to 7" sizes with grits from 30 to 3000, custom specifications available upon request. These pads effectively process natural stone, engineered surfaces and metals with consistent results, making them essential for stone processing and maintenance while providing distributors and traders with excellent inventory options.

Compatible Materials & Products

Granite > Countertops & Memorials

Marble > Luxury Floors & Decorative Elements

Concrete > Industrial Floors & Surfaces

Quartz > Precision Edge Details

Terrazzo > Commercial Flooring

3 Steps Diamond Polishing Pads Demo

Granite's durability and aesthetic appeal make it the preferred choice for kitchen countertops and memorial monuments, requiring high-quality polishing to reveal its natural beauty.

DINOSAW diamond polishing pads use calibrated diamond concentration and strategic particle arrangement to efficiently work with granite's crystalline structure. Starting with coarser grits (50-100) for initial grinding, then progressing through medium (200-400) and fine grits (800-3000), these pads create a systematic refinement process that removes scratches while developing a high-gloss finish on both flat surfaces and edge details.

Stone fabricators achieve consistent polish across varied granite types, while distributors benefit from reliable product performance and reduced customer support requirements.

Granite > Countertops & Memorials

Marble > Luxury Floors & Decorative Elements

Concrete > Industrial Floors & Surfaces

Quartz > Precision Edge Details

Terrazzo > Commercial Flooring

3 Steps Diamond Polishing Pads Demo

Granite's durability and aesthetic appeal make it the preferred choice for kitchen countertops and memorial monuments, requiring high-quality polishing to reveal its natural beauty.

DINOSAW diamond polishing pads use calibrated diamond concentration and strategic particle arrangement to efficiently work with granite's crystalline structure. Starting with coarser grits (50-100) for initial grinding, then progressing through medium (200-400) and fine grits (800-3000), these pads create a systematic refinement process that removes scratches while developing a high-gloss finish on both flat surfaces and edge details.

Stone fabricators achieve consistent polish across varied granite types, while distributors benefit from reliable product performance and reduced customer support requirements.

Consult DINOSAW Material Expert →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Speed up concrete restoration →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Speed up concrete restoration →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Speed up concrete restoration →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Speed up concrete restoration →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Specs and options

Specifications customizable upon request.

For our complete range of diamond polishing pads with various specifications, contact our technical team for parameter sheets and custom options.

DINOSAW diamond tool experts will recommend the optimal pad type, grit sequence, and specifications for your project.

Contact DINOSAW technical team for details →

Engineered for consistent performance across different materials

Complete Polishing Solutions for All Stone Applications

Comprehensive Product Range

Complete selection of wet, dry and hybrid pads covering all stone polishing applications from 30 to 3000 grit

Material-Specific Formulations

Optimized diamond concentration and bonding technology for specific materials from granite to engineered stone

Extended Service Life

Resin bond technology increases pad durability and delivers consistent performance throughout the pad's service life

Inqury for Details →

Multiple Backing Options

Hook and loop, PSA, and snail lock backing systems compatible with all standard polishing equipment

Systematic Color Coding

Clear identification system prevents confusion during progressive polishing sequences, improving workflow efficiency

Distributor Support Program

Comprehensive inventory solutions, merchandising displays, and technical training for trade partners

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Automatic Blade Changing CNC Stone Polishing Machine

This intelligent polishing system features visual recognition and AI algorithms for precise grinding area division and path planning. With one-click parameter setting and automatic tool changing, it efficiently processes various materials including marble, granite, and engineered stone for high-precision applications.

Transform your stone polishing with AI-powered polisher →

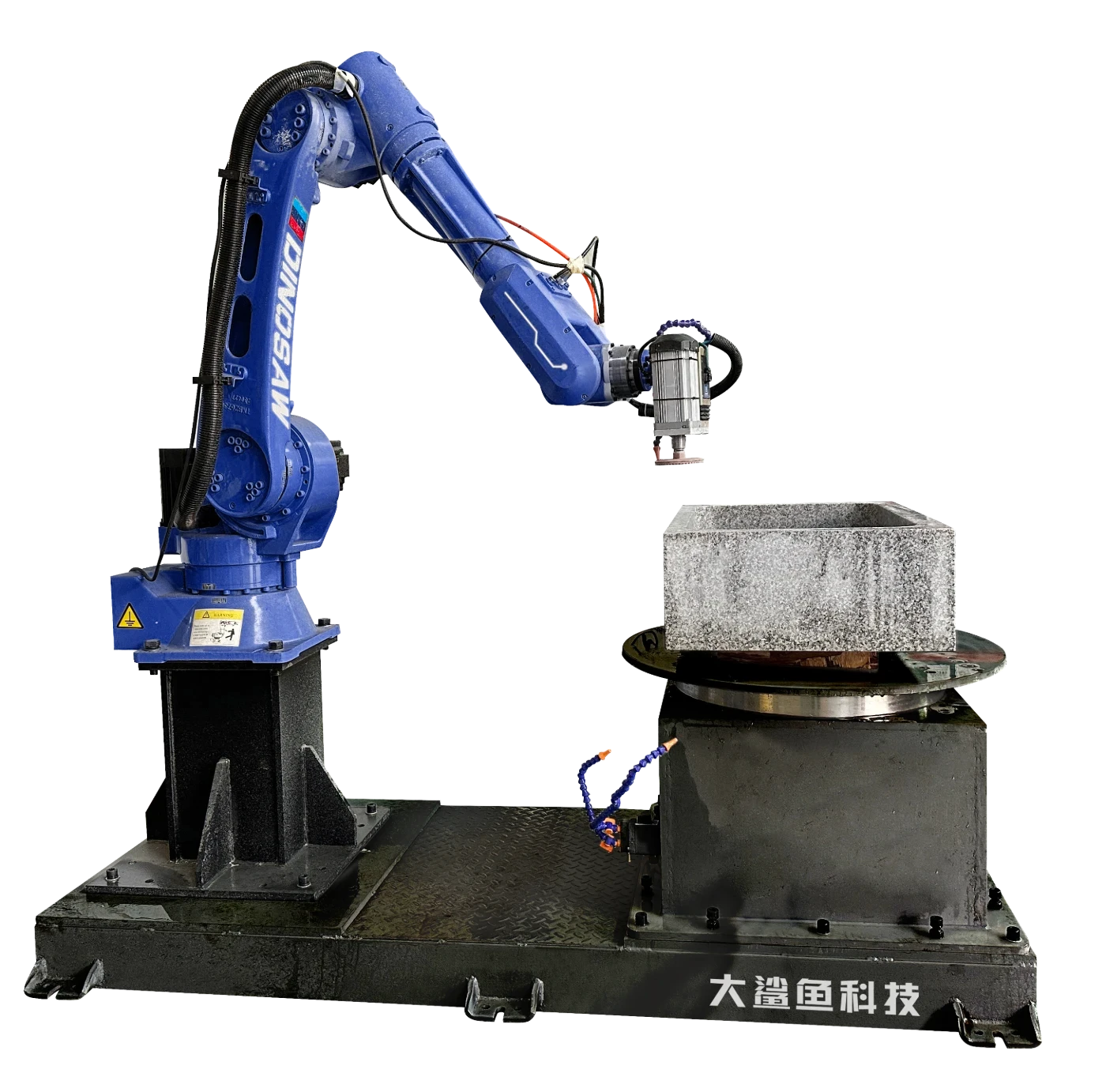

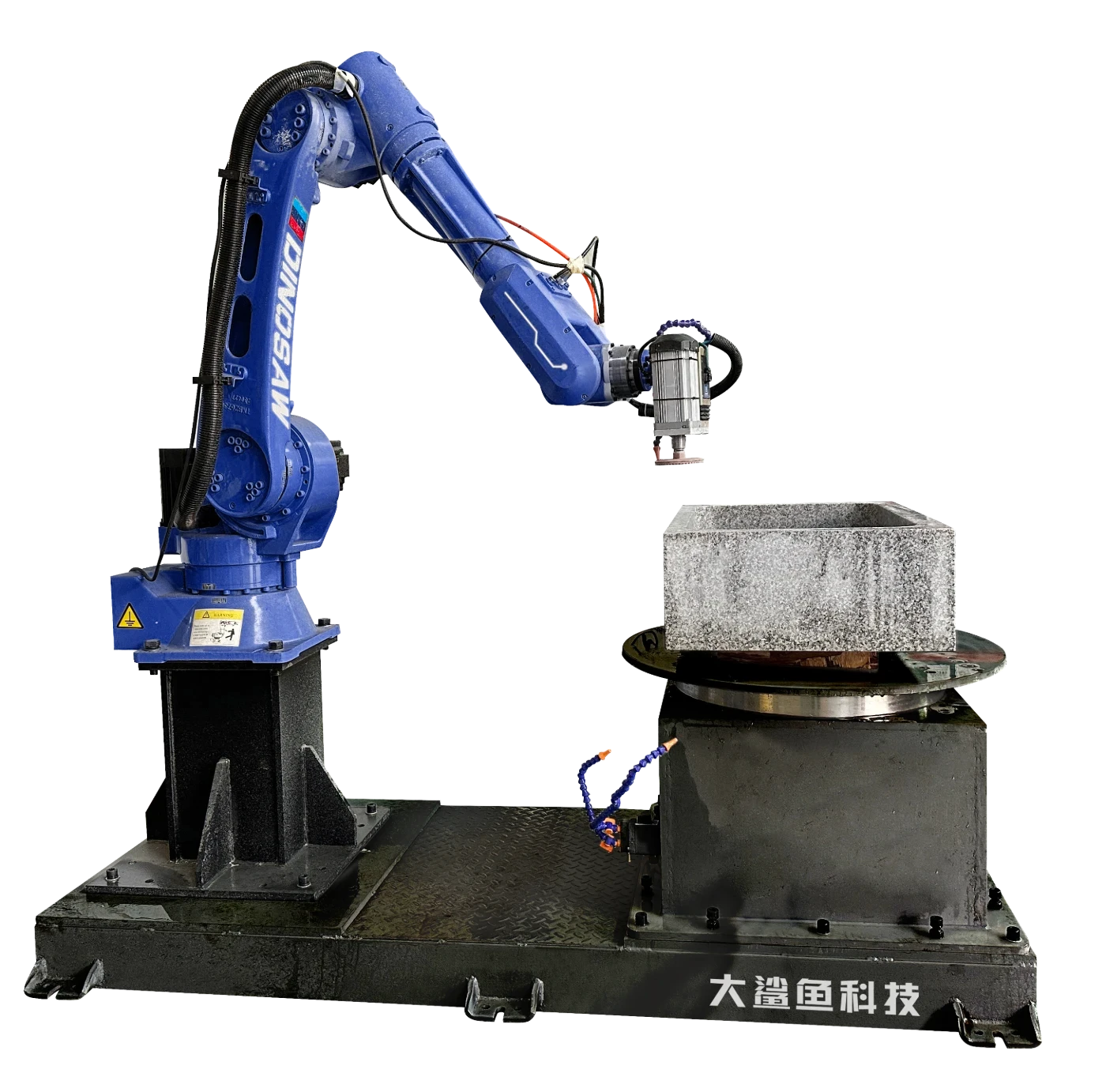

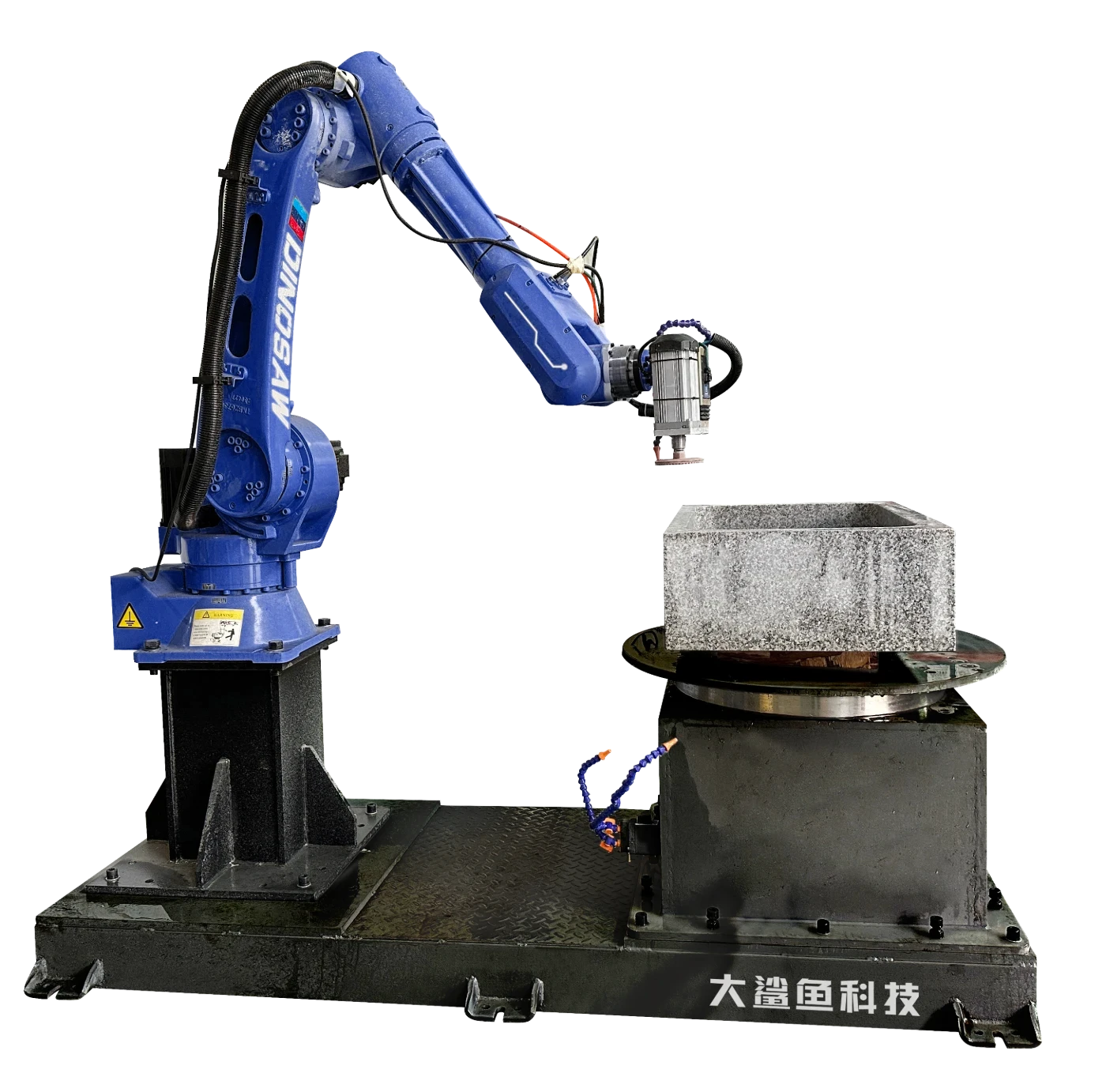

Robot Arm for Automatic Polishing

This automated polishing solution delivers consistent results on complex stone surfaces with programmable paths for edges, curves and detailed areas. Featuring advanced pressure sensing and adaptive control, it ensures uniform finish quality while reducing operator fatigue and labor costs.

Automate complex stone finishing with robotic precision →

Fully-Automatic Multi-Head Stone Polishing Machine

This continuous polishing system features 8-24 customizable grinding heads for high efficiency and low power consumption. Processing over 300 square meters daily with minimal labor, it delivers consistent results on marble, granite, and microcrystalline surfaces with precise speed control.

Boost production capacity with continuous polishing technology →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Polishing Pads

What is the difference between wet and dry diamond polishing pads?

How do I choose the right diamond polishing pad for my specific material?

Are DINOSAW diamond pads compatible with all polishing machines?

What makes DINOSAW diamond polishing pads better than competitors?

Need more assistance? Click to contact DINOSAW →

Professional Diamond Polishing Solutions for Every Application

Contact DINOSAW experts for technical specifications, distributor programs, or customized solutions for specific project requirements.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Diamond Polishing Pads Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Diamond Polishing Excellence: Technical Resources & Guides

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

Diamond Polishing Pads for Granite, Marble & Concrete

Wet/Dry Diamond Polishing Pads for sale

DINOSAW diamond polishing pads polish surfaces and edges of granite, marble, quartz, terrazzo and concrete used in countertops, tabletops, flooring and decorative elements. Available in wet, dry and hybrid options. Offered in 3" to 7" sizes with grits from 30 to 3000, custom specifications available upon request. These pads effectively process natural stone, engineered surfaces and metals with consistent results, making them essential for stone processing and maintenance while providing distributors and traders with excellent inventory options.

Compatible Materials & Products

Granite > Countertops & Memorials

Marble > Luxury Floors & Decorative Elements

Concrete > Industrial Floors & Surfaces

Quartz > Precision Edge Details

Terrazzo > Commercial Flooring

3 Steps Diamond Polishing Pads Demo

Granite's durability and aesthetic appeal make it the preferred choice for kitchen countertops and memorial monuments, requiring high-quality polishing to reveal its natural beauty.

DINOSAW diamond polishing pads use calibrated diamond concentration and strategic particle arrangement to efficiently work with granite's crystalline structure. Starting with coarser grits (50-100) for initial grinding, then progressing through medium (200-400) and fine grits (800-3000), these pads create a systematic refinement process that removes scratches while developing a high-gloss finish on both flat surfaces and edge details.

Stone fabricators achieve consistent polish across varied granite types, while distributors benefit from reliable product performance and reduced customer support requirements.

Granite > Countertops & Memorials

Marble > Luxury Floors & Decorative Elements

Concrete > Industrial Floors & Surfaces

Quartz > Precision Edge Details

Terrazzo > Commercial Flooring

3 Steps Diamond Polishing Pads Demo

Granite's durability and aesthetic appeal make it the preferred choice for kitchen countertops and memorial monuments, requiring high-quality polishing to reveal its natural beauty.

DINOSAW diamond polishing pads use calibrated diamond concentration and strategic particle arrangement to efficiently work with granite's crystalline structure. Starting with coarser grits (50-100) for initial grinding, then progressing through medium (200-400) and fine grits (800-3000), these pads create a systematic refinement process that removes scratches while developing a high-gloss finish on both flat surfaces and edge details.

Stone fabricators achieve consistent polish across varied granite types, while distributors benefit from reliable product performance and reduced customer support requirements.

Consult DINOSAW Material Expert →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Kitchen Countertop Fabrication

Achieving Perfect Edge Details and Surface Polish in Half the Time

Chicago countertop fabricator using DINOSAW diamond polishing pads reduced polishing time by 40% while improving edge consistency. Extended pad life and lower labor costs increased profit margins despite market pricing pressures.

Boost countertop production efficiency →

Concrete Floor Restoration

Transforming Worn Industrial Spaces into Premium Environments

Renovation specialist transformed 15,000 sq ft warehouse concrete into modern office flooring using DINOSAW concrete-specific diamond pads. Project completed 3 days early with high-gloss, low-maintenance surface that reduced ongoing costs.

Perfect your monument finishes →

Memorial Stone Finishing

Honoring Memories with Flawless, Enduring Craftsmanship

Monument company achieved deeper blacks, vibrant colors and perfect surface reflection on diverse granites with DINOSAW diamond pads. Improved finish quality enabled premium pricing while extended pad life reduced production costs by 22%.

Perfect your monument finishes →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

For our complete range of diamond polishing pads with various specifications, contact our technical team for parameter sheets and custom options.

DINOSAW diamond tool experts will recommend the optimal pad type, grit sequence, and specifications for your project.

Contact DINOSAW technical team for details →

Engineered for consistent performance across different materials

Complete Polishing Solutions for All Stone Applications

Comprehensive Product Range

Complete selection of wet, dry and hybrid pads covering all stone polishing applications from 30 to 3000 grit

Material-Specific Formulations

Optimized diamond concentration and bonding technology for specific materials from granite to engineered stone

Extended Service Life

Resin bond technology increases pad durability and delivers consistent performance throughout the pad's service life

Inqury for Details →

Comprehensive Product Range

Complete selection of wet, dry and hybrid pads covering all stone polishing applications from 30 to 3000 grit

Material-Specific Formulations

Optimized diamond concentration and bonding technology for specific materials from granite to engineered stone

Extended Service Life

Resin bond technology increases pad durability and delivers consistent performance throughout the pad's service life

Inqury for Details →

Multiple Backing Options

Hook and loop, PSA, and snail lock backing systems compatible with all standard polishing equipment

Systematic Color Coding

Clear identification system prevents confusion during progressive polishing sequences, improving workflow efficiency

Distributor Support Program

Comprehensive inventory solutions, merchandising displays, and technical training for trade partners

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Automatic Blade Changing CNC Stone Polishing Machine

This intelligent polishing system features visual recognition and AI algorithms for precise grinding area division and path planning. With one-click parameter setting and automatic tool changing, it efficiently processes various materials including marble, granite, and engineered stone for high-precision applications.

Transform your stone polishing with AI-powered polisher →

Robot Arm for Automatic Polishing

This automated polishing solution delivers consistent results on complex stone surfaces with programmable paths for edges, curves and detailed areas. Featuring advanced pressure sensing and adaptive control, it ensures uniform finish quality while reducing operator fatigue and labor costs.

Automate complex stone finishing with robotic precision →

Fully-Automatic Multi-Head Stone Polishing Machine

This continuous polishing system features 8-24 customizable grinding heads for high efficiency and low power consumption. Processing over 300 square meters daily with minimal labor, it delivers consistent results on marble, granite, and microcrystalline surfaces with precise speed control.

Boost production capacity with continuous polishing technology →

Bridge Single-head Automatic Stone Polisher

This bridge polisher achieves excellent surface quality comparable to continuous grinding machines. Processing materials up to 3x2m in size. The stable automatic movement system is ideal for tombstones and projects requiring thickness adjustments.

Achieve continuous-quality results →

Get a Custom Solution →

Faqs

Common Questions About DINOSAW Diamond Polishing Pads

What is the difference between wet and dry diamond polishing pads?

What is the difference between wet and dry diamond polishing pads?

How do I choose the right diamond polishing pad for my specific material?

How do I choose the right diamond polishing pad for my specific material?

Are DINOSAW diamond pads compatible with all polishing machines?

Are DINOSAW diamond pads compatible with all polishing machines?

What makes DINOSAW diamond polishing pads better than competitors?

What makes DINOSAW diamond polishing pads better than competitors?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Professional Diamond Polishing Solutions for Every Application

Diamond Polishing Excellence: Technical Resources & Guides

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Diamond Polishing Pads Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Diamond Polishing Excellence: Technical Resources & Guides

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?