CNC Diamond Wire Saw Machine | Irregular Cutting & Profiling Expert

YXSJ-2500/3000/3500-16H

DINOSAW CNC diamond wire saw cuts hard materials with 1mm precision and smooth finish. Cuts complex shapes without heat or vibration damage. Processes materials up to several meters thick with easy operation and 5-min training time. Cuts stone, concrete, metals, graphite, fiberglass, quartz glass and composites with custom shapes and minimal waste. Ideal for tombstones, architectural elements, sculptures, metal equipment and concrete demolition.

Compatible Materials & Products

Natural Stone > Tombstones & Monuments

Stone > Artistic Sculptures

Concrete > Building Components

Metals > Industrial Parts

Quartz Glass > Precision Components

▶ Product Demo

|

|---|

|

|

|

|

The memorial industry demands intricate designs and flawless finishes on hard granite and marble, creating unique challenges for traditional cutting methods.

DINOSAW CNC diamond wire saw machine transforms this process through its precision cutting technology, enabling perfect execution of complex patterns, curves, and decorative elements essential for premium tombstones and monuments. The wire saw's ability to cut any angle and shape with minimal material loss increases yield by up to 30%, delivering superior craftsmanship while maximizing profitability.

Natural Stone > Tombstones & Monuments

Stone > Artistic Sculptures

Concrete > Building Components

Metals > Industrial Parts

Quartz Glass > Precision Components

▶ Product Demo

|

|---|

|

|

|

|

The memorial industry demands intricate designs and flawless finishes on hard granite and marble, creating unique challenges for traditional cutting methods.

DINOSAW CNC diamond wire saw machine transforms this process through its precision cutting technology, enabling perfect execution of complex patterns, curves, and decorative elements essential for premium tombstones and monuments. The wire saw's ability to cut any angle and shape with minimal material loss increases yield by up to 30%, delivering superior craftsmanship while maximizing profitability.

Consult DINOSAW Material Expert →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Upgrade your pipe manufacturing precision →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Upgrade your pipe manufacturing precision →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Upgrade your pipe manufacturing precision →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Upgrade your pipe manufacturing precision →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Specs and options

Specifications customizable upon request.

Model | Unit | YXSJ-2500-16H | YXSJ-3000-16H | YXSJ-3500-16H |

Max working dimensions | m | 2.5×1.5 | 3.0×1.5 | 3.5×1.5 |

Worktable size | m | 2.5×1.4 | 2.5×1.4 | 2.5×1.4 |

Wire diameter | mm | 7.6 - 11 | 7.6 - 11 | 7.6 - 11 |

Main motor power | kw | 15 | 15 | 15 |

Water consumption | m³/h | 3 | 3 | 3 |

Overall dimensions | m | 6.3×7.2×4.0 | 6.3×7.7×4.0 | 6.3×8.2×4.0 |

Approximate weight | t | 6.8 | 7.6 | 8.5 |

Contact DINOSAW technical team for details →

Wire saw technology delivering precision cuts across hard materials

Any Material, Any Shape with CNC Precision

Rapid 5-Minute Setup & Operation

In-house developed CNC system eliminates programming requirements

Precision Cutting Within ±1mm

Hydraulic tensioning paired with servo motor technology ensures consistent wire pressure

Twice the Cutting Speed

Cutting marble at 2m²/h using advanced industrial permanent magnet motor technology

Inqury for Details →

Rapid 5-Minute Setup & Operation

In-house developed CNC system eliminates programming requirements

Precision Cutting Within ±1mm

Hydraulic tensioning paired with servo motor technology ensures consistent wire pressure

Twice the Cutting Speed

Cutting marble at 2m²/h using advanced industrial permanent magnet motor technology

Inqury for Details →

Reduces Energy Usage by 20%

Equipped with energy-efficient permanent magnet synchronous motor technology

Control From Anywhere

Integrated OTA capabilities enable remote software updates and maintenance assistance

Shapes Beyond Limitations

Create straight lines, curves, and custom designs through advanced multi-axis control technology

Built to Last

Superior durability through iron cast framework enhanced with premium Siemens and NSK components

Complete Safety Systems

Comprehensive protection through integrated software alerts, protective covers and limit switch technology

Minimal Maintenance Required

Features dust and moisture protection plus built-in automatic lubrication mechanisms

FAQs

Common Questions About CNC Diamond Wire Saw Machine

What materials can the CNC diamond wire saw machine cut?

What materials can the CNC diamond wire saw machine cut?

What is the precision level of the CNC diamond wire saw machine?

What is the precision level of the CNC diamond wire saw machine?

How easy is it to operate the CNC diamond wire saw machine?

How easy is it to operate the CNC diamond wire saw machine?

How to prevent diamond wire breakage during cutting operations?

How to prevent diamond wire breakage during cutting operations?

What maintenance is required for the CNC diamond wire saw machine?

What maintenance is required for the CNC diamond wire saw machine?

Need more assistance? Click to contact DINOSAW →

Certifications & Standards

Global Leader in Industrial Machinery & Diamond Tools Manufacturing

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Automatic Polishing Machine

DINOSAW grinding machines combine visual recognition with multi-head design for stone surface finishing. CNC controls ensure quality on marble, granite, glass and engineered stone. Reduces labor by 65% while smart pressure control extends tool life and creates mirror finishes.

Explore visual recognition for perfect surface finishing →

7-Axis CNC Carving Robotic Arm

DINOSAW 7-axis robot uses KUKA technology for 3D stone carving. SprutCAM software handles detailed sculptures, architectural elements and decorative panels. Perfect for Buddha statues, church sculptures and ornamental features.

Enhance your stone carving with robotic precision →

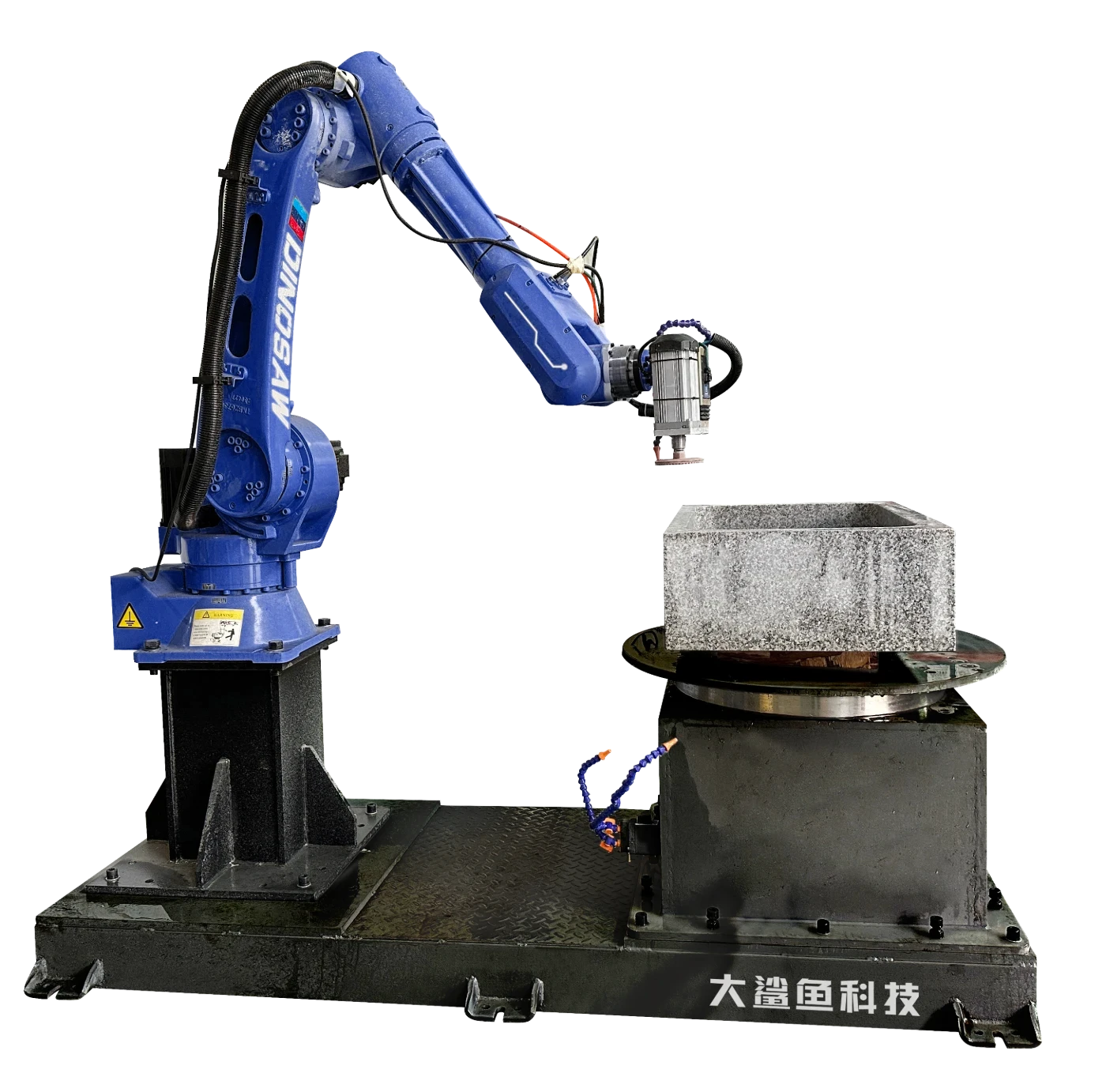

6-Axis Robotic Arm for Precision Polishing

DINOSAW 6-axis polishing robot provides mobility for surface finishing, edge work and detail polishing. Handles granite, marble and engineered stone with adaptive force control. Ideal for tombstones, countertops and sculptures needing consistent finishes.

Upgrade your polishing with robotic precision →

Get a Custom Solution

Ready to Transform Your Complex Cutting Capabilities?

Contact DINOSAW today for a personalized demonstration and material test cutting to see how our CNC wire saw technology can revolutionize your production.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Wire Saw Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Complex Cutting: Insights & Applications

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC Diamond Wire Saw Machine | Irregular Cutting & Profiling Expert

YXSJ-2500/3000/3500-16H

DINOSAW CNC diamond wire saw cuts hard materials with 1mm precision and smooth finish. Cuts complex shapes without heat or vibration damage. Processes materials up to several meters thick with easy operation and 5-min training time. Cuts stone, concrete, metals, graphite, fiberglass, quartz glass and composites with custom shapes and minimal waste. Ideal for tombstones, architectural elements, sculptures, metal equipment and concrete demolition.

Compatible Materials & Products

Natural Stone > Tombstones & Monuments

Stone > Artistic Sculptures

Concrete > Building Components

Metals > Industrial Parts

Quartz Glass > Precision Components

▶ Product Demo

|

|---|

|

|

|

|

The memorial industry demands intricate designs and flawless finishes on hard granite and marble, creating unique challenges for traditional cutting methods.

DINOSAW CNC diamond wire saw machine transforms this process through its precision cutting technology, enabling perfect execution of complex patterns, curves, and decorative elements essential for premium tombstones and monuments. The wire saw's ability to cut any angle and shape with minimal material loss increases yield by up to 30%, delivering superior craftsmanship while maximizing profitability.

Natural Stone > Tombstones & Monuments

Stone > Artistic Sculptures

Concrete > Building Components

Metals > Industrial Parts

Quartz Glass > Precision Components

▶ Product Demo

|

|---|

|

|

|

|

The memorial industry demands intricate designs and flawless finishes on hard granite and marble, creating unique challenges for traditional cutting methods.

DINOSAW CNC diamond wire saw machine transforms this process through its precision cutting technology, enabling perfect execution of complex patterns, curves, and decorative elements essential for premium tombstones and monuments. The wire saw's ability to cut any angle and shape with minimal material loss increases yield by up to 30%, delivering superior craftsmanship while maximizing profitability.

Consult DINOSAW Material Expert →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Artistic Stone Craftsmanship

Transform Hard Granite into Premium Memorial Masterpieces

Stone manufacturer adopted DINOSAW CNC wire saw for complex production needs. Results: 40% faster production, 28% less waste, and complex curved designs impossible with traditional methods.

Transform your stone craftsmanship with precision →

Fiberglass Pipe Engineering

Zero-Defect Precision for Industrial Pipe Systems

Fiberglass manufacturer solved rejection problems on large pipes with complex openings using DINOSAW CNC wire saw. The system eliminated delamination while creating precise angle cuts and custom openings. Higher quality secured their reputation as a premium supplier.

Master metal recycling with power and safety →

Heavy Metal Demolition

Safe Dismantling of Massive Industrial Structures

Metal recycling company overcame challenges with massive structures using DINOSAW CNC technology. The system cut metal frameworks up to 2 meters thick with precision. Processing capacity increased 65% while workplace injuries decreased significantly due to vibration-free cutting technology.

Master metal recycling with power and safety →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | YXSJ-2500-16H | YXSJ-3000-16H | YXSJ-3500-16H |

Max working dimensions | m | 2.5×1.5 | 3.0×1.5 | 3.5×1.5 |

Worktable size | m | 2.5×1.4 | 2.5×1.4 | 2.5×1.4 |

Wire diameter | mm | 7.6 - 11 | 7.6 - 11 | 7.6 - 11 |

Main motor power | kw | 15 | 15 | 15 |

Water consumption | m³/h | 3 | 3 | 3 |

Overall dimensions | m | 6.3×7.2×4.0 | 6.3×7.7×4.0 | 6.3×8.2×4.0 |

Approximate weight | t | 6.8 | 7.6 | 8.5 |

Contact DINOSAW technical team for details →

Wire saw technology delivering precision cuts across hard materials

Any Material, Any Shape with CNC Precision

Rapid 5-Minute Setup & Operation

In-house developed CNC system eliminates programming requirements

Precision Cutting Within ±1mm

Hydraulic tensioning paired with servo motor technology ensures consistent wire pressure

Twice the Cutting Speed

Cutting marble at 2m²/h using advanced industrial permanent magnet motor technology

Inqury for Details →

Rapid 5-Minute Setup & Operation

In-house developed CNC system eliminates programming requirements

Precision Cutting Within ±1mm

Hydraulic tensioning paired with servo motor technology ensures consistent wire pressure

Twice the Cutting Speed

Cutting marble at 2m²/h using advanced industrial permanent magnet motor technology

Inqury for Details →

Reduces Energy Usage by 20%

Equipped with energy-efficient permanent magnet synchronous motor technology

Control From Anywhere

Integrated OTA capabilities enable remote software updates and maintenance assistance

Shapes Beyond Limitations

Create straight lines, curves, and custom designs through advanced multi-axis control technology

Built to Last

Superior durability through iron cast framework enhanced with premium Siemens and NSK components

Complete Safety Systems

Comprehensive protection through integrated software alerts, protective covers and limit switch technology

Minimal Maintenance Required

Features dust and moisture protection plus built-in automatic lubrication mechanisms

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Automatic Polishing Machine

DINOSAW grinding machines combine visual recognition with multi-head design for stone surface finishing. CNC controls ensure quality on marble, granite, glass and engineered stone. Reduces labor by 65% while smart pressure control extends tool life and creates mirror finishes.

Explore visual recognition for perfect surface finishing →

7-Axis CNC Carving Robotic Arm

DINOSAW 7-axis robot uses KUKA technology for 3D stone carving. SprutCAM software handles detailed sculptures, architectural elements and decorative panels. Perfect for Buddha statues, church sculptures and ornamental features.

Enhance your stone carving with robotic precision →

6-Axis Robotic Arm for Precision Polishing

DINOSAW 6-axis polishing robot provides mobility for surface finishing, edge work and detail polishing. Handles granite, marble and engineered stone with adaptive force control. Ideal for tombstones, countertops and sculptures needing consistent finishes.

Upgrade your polishing with robotic precision →

Get a Custom Solution →

FAQs

Common Questions About CNC Diamond Wire Saw Machine

What materials can the CNC diamond wire saw machine cut?

What materials can the CNC diamond wire saw machine cut?

What is the precision level of the CNC diamond wire saw machine?

What is the precision level of the CNC diamond wire saw machine?

How easy is it to operate the CNC diamond wire saw machine?

How easy is it to operate the CNC diamond wire saw machine?

How to prevent diamond wire breakage during cutting operations?

How to prevent diamond wire breakage during cutting operations?

Need more assistance? Contact DINOSAW →

Global Leader in Industrial

Machinery & Diamond Tools

Manufacturing

Certifications & Standards

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

DINOSAW delivers lifecycle quality traceability and technical support for machinery equipment and diamond tools, covering cutting, drilling, engraving, polishing, and processing requirements for precision machining across industries.

Our products serve traditional industries (mining, stone processing, building materials), high-precision manufacturing (quartz glass, semiconductor), advanced materials (graphite, carbon fiber composites), and specialized applications (nuclear decommissioning, railway construction machinery).

75+

Countries Served Worldwide

20+

Industry machinery expertise

Ready to Transform Your Complex Cutting Capabilities?

Master Complex Cutting: Insights & Applications

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Wire Saw Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Complex Cutting: Insights & Applications

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?

Hello 👋 How can we help?