CNC Wire Saw Machine Introduction

Dinosaw CNC wire saws are designed for efficient cutting of materials such as stone, metal, and glass. Whether you need precision cutting or large-scale industrial processing, Dinosaw provides reliable solutions. We are committed to ensuring your success through advanced technology and comprehensive after-sales support to keep your operations running smoothly.

Inverter Communication Failure - Solution

This video will guide you on how to resolve the inverter communication failure issue. Please follow the steps below:

Step 1: Check the 485 Adapter

Start by checking if the inverter screen displays values normally.

If the display is normal, check the 485 adapter for any damage.

Replace the 485 adapter connected to the main motor with one of the other three working adapters for temporary use.

If the issue is resolved, the 485 adapter is confirmed to be damaged and should be replaced.

If replacing the 485 adapter does not resolve the issue, contact Dinosaw’s after-sales service.

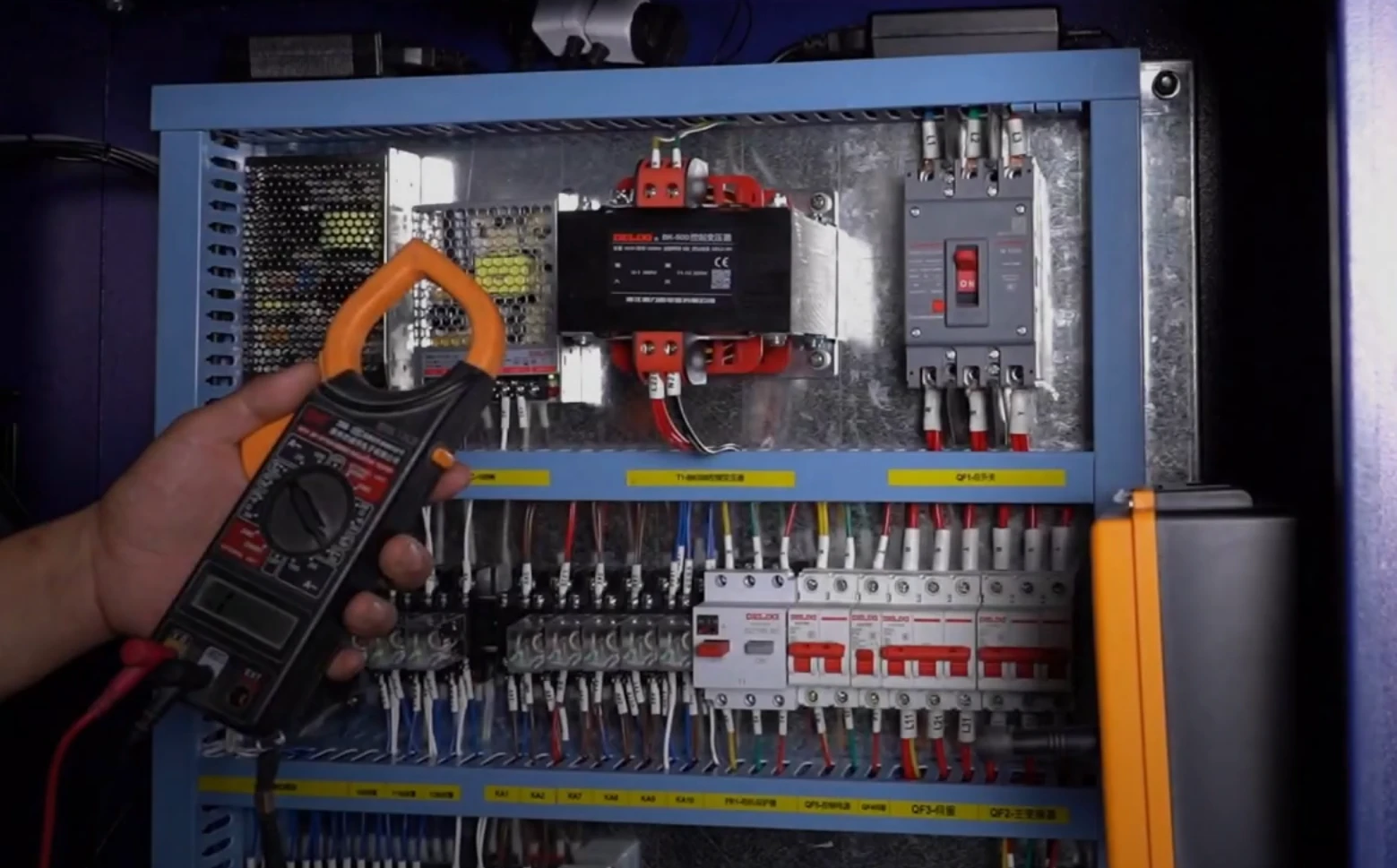

Step 2: Inspect the Circuit

If the inverter screen does not display values normally, turn off the corresponding control switch and disconnect the UVW wires from below the inverter.

Re-enable the controller and begin inspecting the circuit. Use a multimeter to check the voltage of the circuit components, ensuring that all three circuit paths (upper and lower) of each component are functioning properly. The steps are as follows:

Check the QF1 main switch, QF2 spindle inverter control, and the spindle inverter.

If any component shows no voltage or abnormal voltage, it indicates a fault in an upstream component or circuit damage. Replace or repair the faulty component as needed.

If the circuit shows no abnormalities but the inverter remains faulty, contact Dinosaw’s after-sales service.

After inspection, reconnect the UVW wires to their original positions.

Keeping Your Wire Saw Machine Running

At Dinosaw, we go beyond just providing machines—we offer comprehensive after-sales support to ensure your success. From installation and training to regular maintenance and system updates, our dedicated team is here to keep your CNC wire saw machine running smoothly. Trust Dinosaw to be your reliable partner every step of the way.