What is a CNC Diamond Wire Saw Cutting Machine?

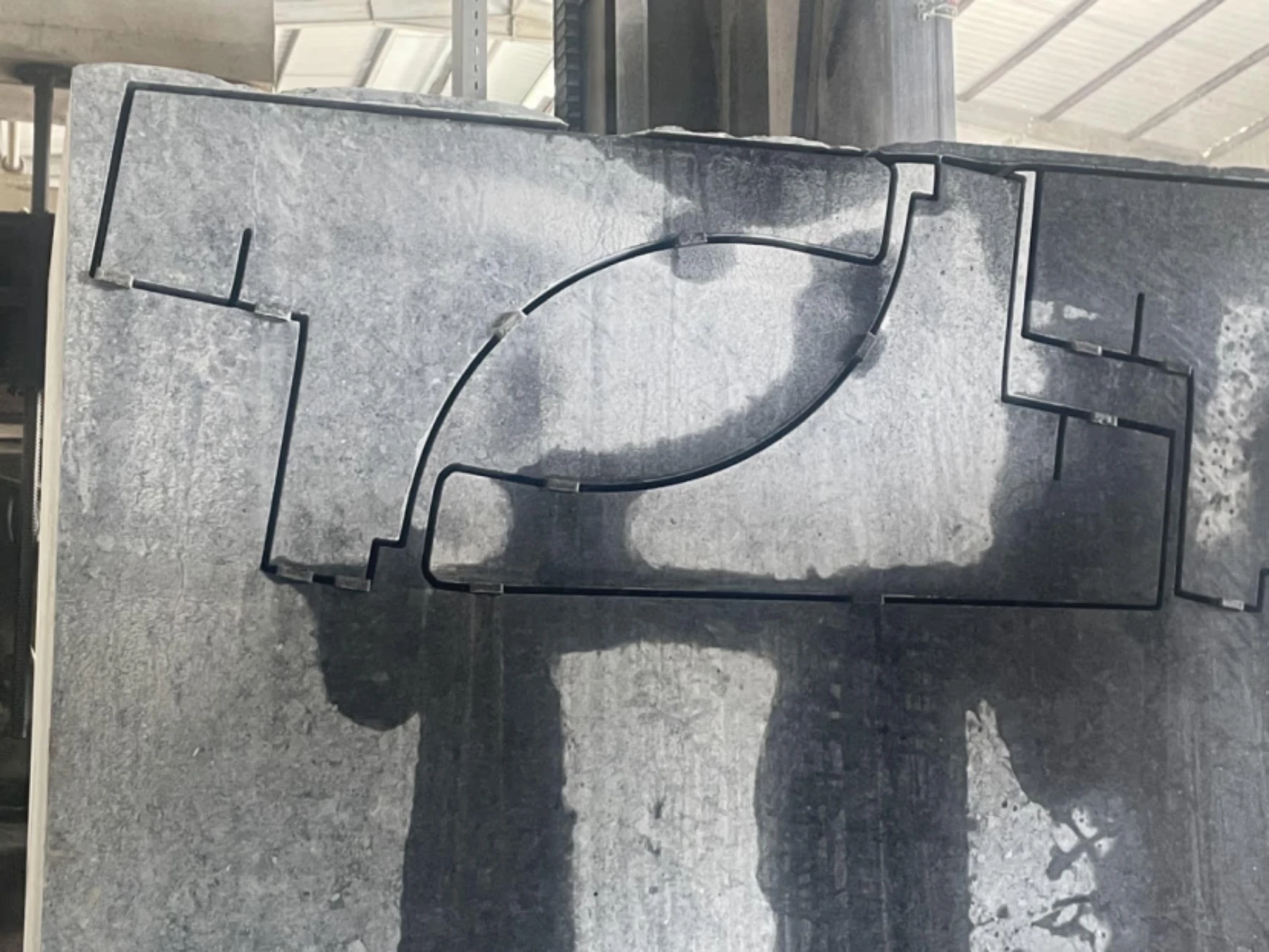

A CNC Diamond Wire Saw Cutting Machine is a specialized equipment used for hard material cutting,such as stone,steel,graphite,concrete,and more. It utilizes a flexible metal wire embedded with diamond particles to achieve precise stone cutting. Driven by the machine, this diamond wire saw rotates at high speed, enabling straight, curved, or complex shape cuts according to preset paths.

The design of a CNC Diamond Wire Saw Cutting Machine allows for exceptional flexibility and accuracy in stone processing, making it ideal for creating stone products with specific shapes and dimensions, such as arcs, circles, ellipses, or other irregular forms.

This machine is often equipped with a CNC system that automates complex cutting tasks, enhancing production efficiency and quality.

Why use a CNC Diamond Wire Saw Cutting Machine?

Flexibility for complex shapes

A wire saw machine can cut complex shapes that traditional saw blades cannot achieve, catering to the demand for personalized and customized stone products in architectural and decorative fields.

Precision to improve material utilization

Precise cutting capability means higher material utilization and less waste, crucial for cost control and resource saving.

High efficiency with automated production

Automation reduces manual operation, decreases labor intensity, and improves production speed and consistency.

Shaped wire saw machines are favored in architectural decoration, sculpture art, tombstone manufacturing, and furniture design. Compared to traditional stone cutting machines like bridge saws, they provide greater design freedom and processing possibilities.

How to choose a CNC Diamond Wire Saw Cutting Machine?

General-purpose stone cutting models

Recommended Models:

Intelligent CNC Wire Saw Machine Pro / Intelligent CNC Wire Saw Machine for granite

Cutting Functions:

Supports multifunctional cutting, including straight, curved, and complex shaped cuts, meeting diverse stone processing needs.

Applications:

Custom furniture: Cutting marble tabletops, granite countertops, stone chairs

Architectural decoration: Cutting stone slabs, stair handrails, stone railings

Interior decoration: Cutting stone fireplace surrounds, kitchen countertops, bathroom countertops

Landscape design: Processing stone benches, stone tables, stone columns

Other hard material cutting: Graphite, alloys, semiconductors, quartz glass, etc.

Maximum Cutting Dimensions:

3000 × 3500mm × 1500mm

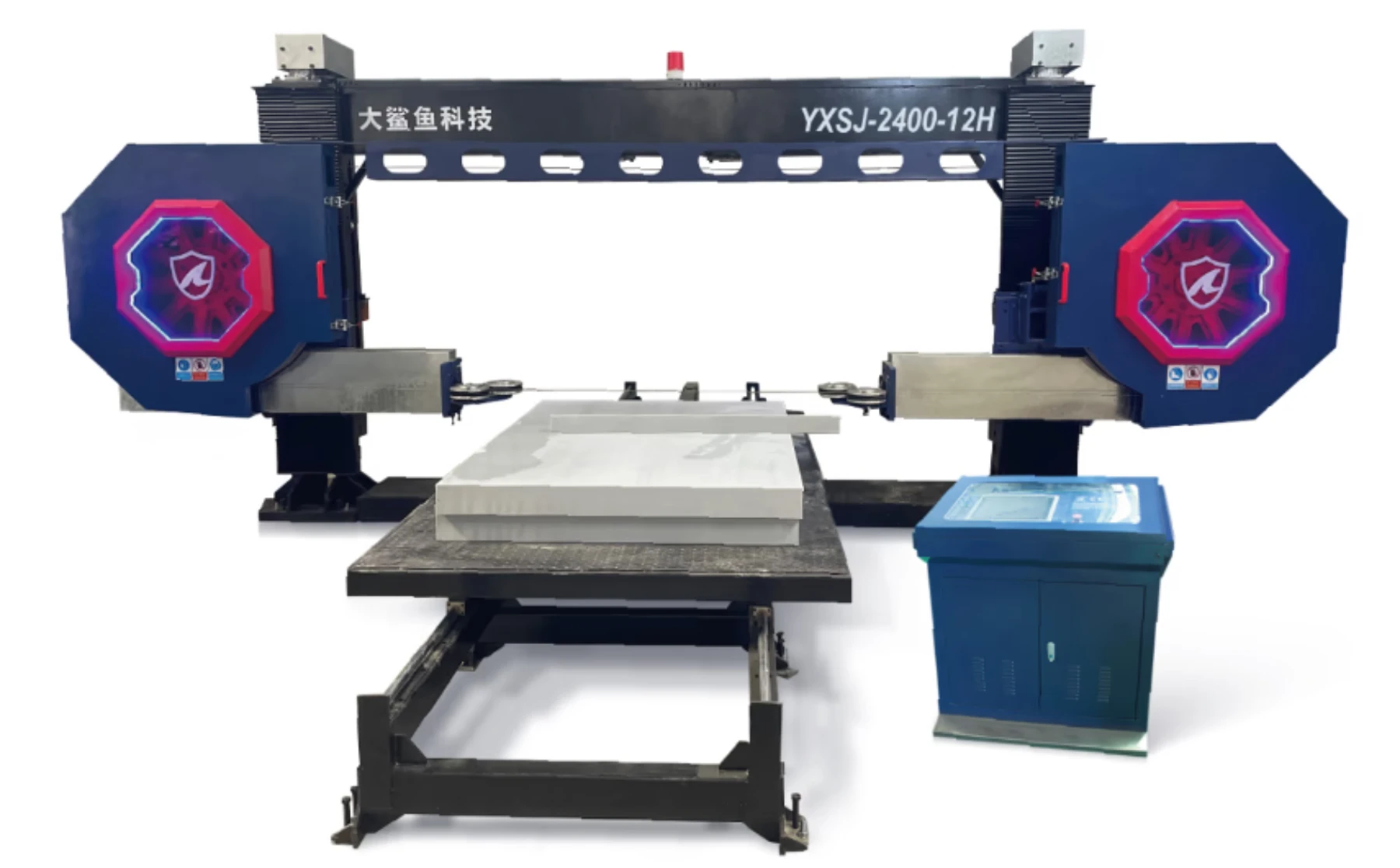

Foamed ceramic cutting models

Recommended Model:

CNC Wire Saw Machine for Foamed Ceramics

Cutting Functions:

Specifically designed for lightweight materials, supporting straight, curved, and shaped cuts to handle complex shapes flexibly.

Applications:

Precise processing of foamed ceramic insulation panels for construction

Shaped cutting of low-density stones or refractory bricks

Customized shape processing of lightweight industrial materials

Maximum Cutting Dimensions:

3000mm × 2400mm × 1100mm

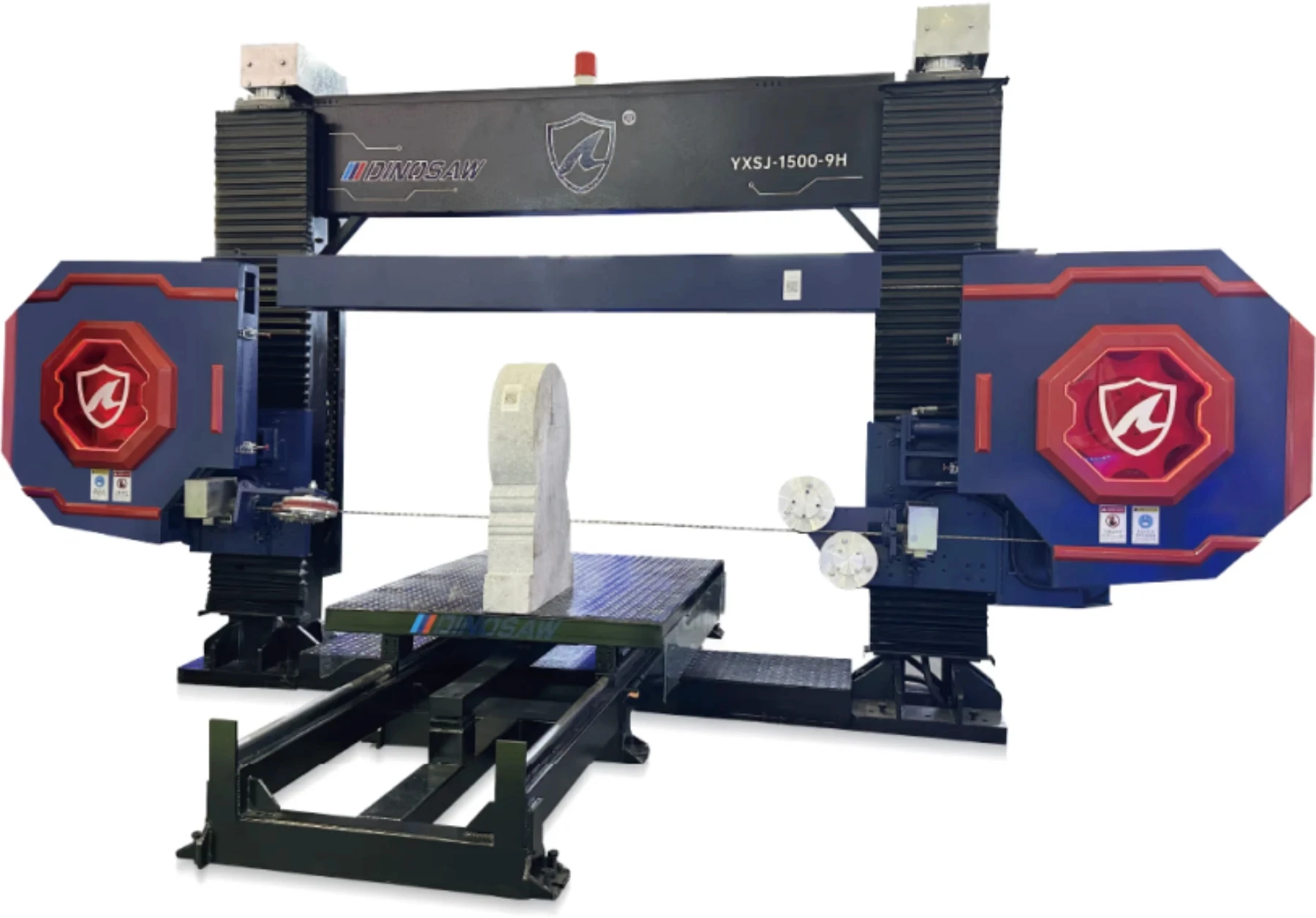

Tombstone cutting models

Recommended Model:

CNC Wire Saw Machine for Profiling Tombstones

Cutting Functions:

Supports straight, curved, and shaped engraving, designed for small-scale stone processing with user-friendly operation and cost-effectiveness.

Applications:

Precision cutting of small tombstones and monuments

Curved and shaped processing for small stone factories

Custom cutting of artistic sculptures or commemorative plaques

Maximum Cutting Dimensions:

1500mm × 1200mm × 800mm

CNC Diamond Wire Saw Cutting Machine Features

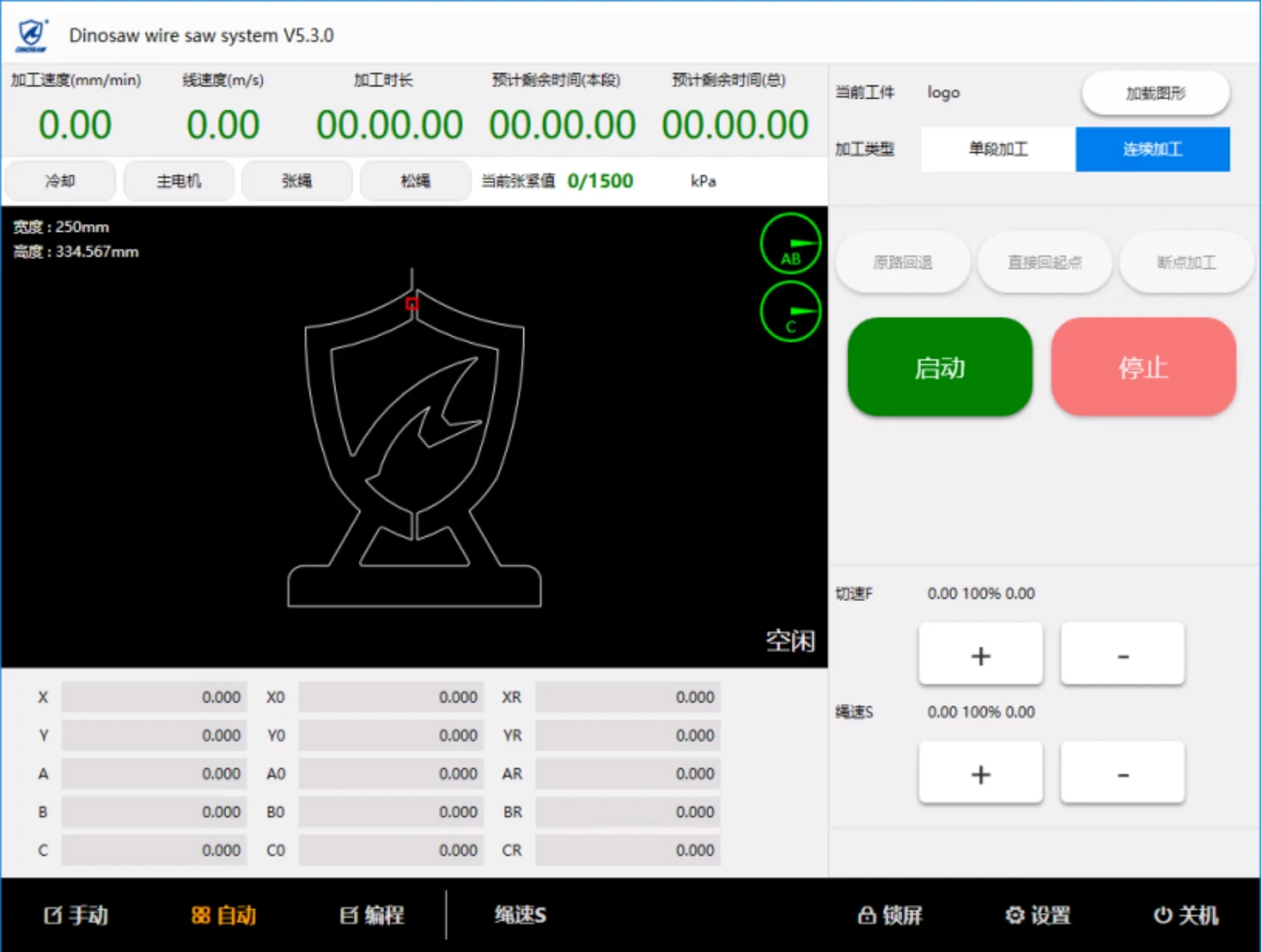

Low learning curve, easy operation

The Dinosaw self-developed CNC intelligent control system shortens the learning period from months to just 5 minutes compared to traditional G-code systems, significantly reducing training and labor costs.

The intuitive interface supports touch screens and direct CAD drawing imports, simplifying workflows and enhancing processing efficiency.

Real-time monitoring of processing data allows flexible adjustments during operations, with automatic alarms for anomalies, ensuring safer and more convenient use.

High cutting precision up to ±1mm

Equipped with an Inovance servo motor and servo system, comined with real-time pressure sensors and hydraulic tensioning devices, it ensures constant cutting pressure. Compared to stepper motors, precision is improved from 3-5mm to ±1mm.

Enhanced processing efficiency

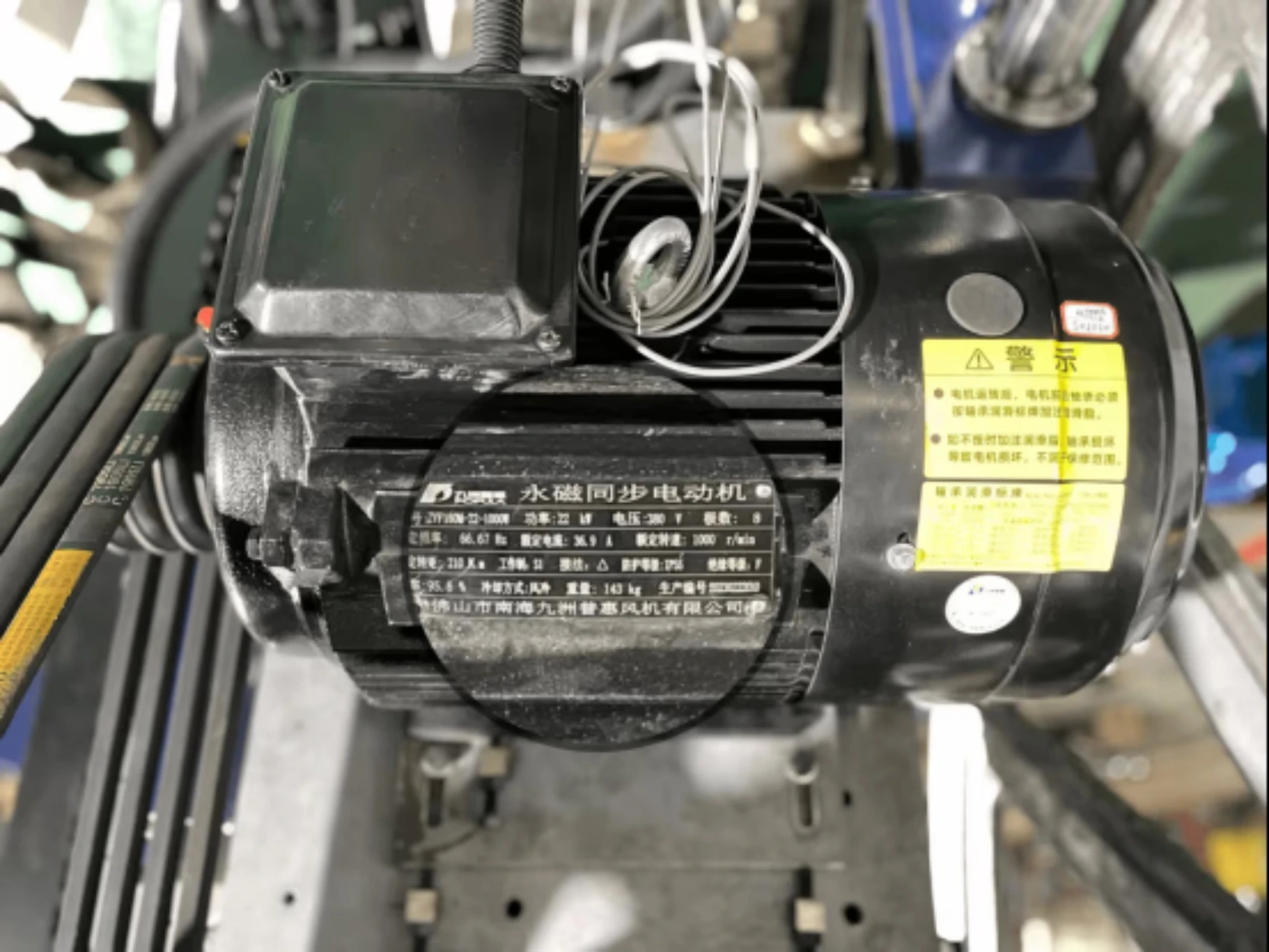

Utilizing a permanent magnet synchronous motor, the processing efficiency for medium-hard marble reaches 1.8-2.5㎡/h, doubling the output while saving over 30% energy compared to standard motors.

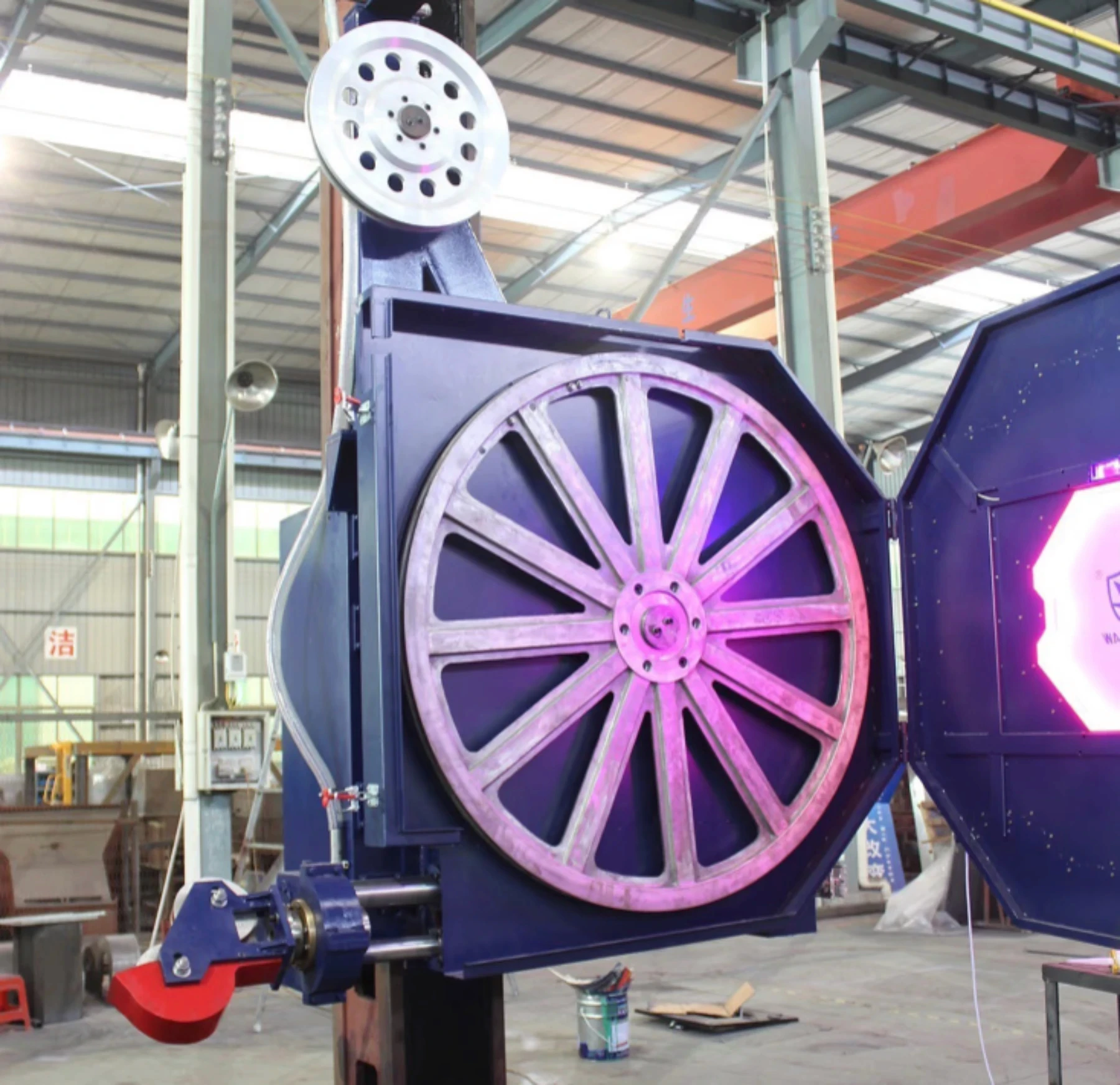

Extended flywheel lifespan

Reinforced flywheel design increases weight by 30% and strength by 20%, with dynamic balancing to reduce vibration and noise, doubling the flywheel's service life.

Stable casting frame structure

Key components like columns and flywheels use cast structures, ensuring smooth operation. Core parts undergo precision machining and heat treatment to minimize errors.

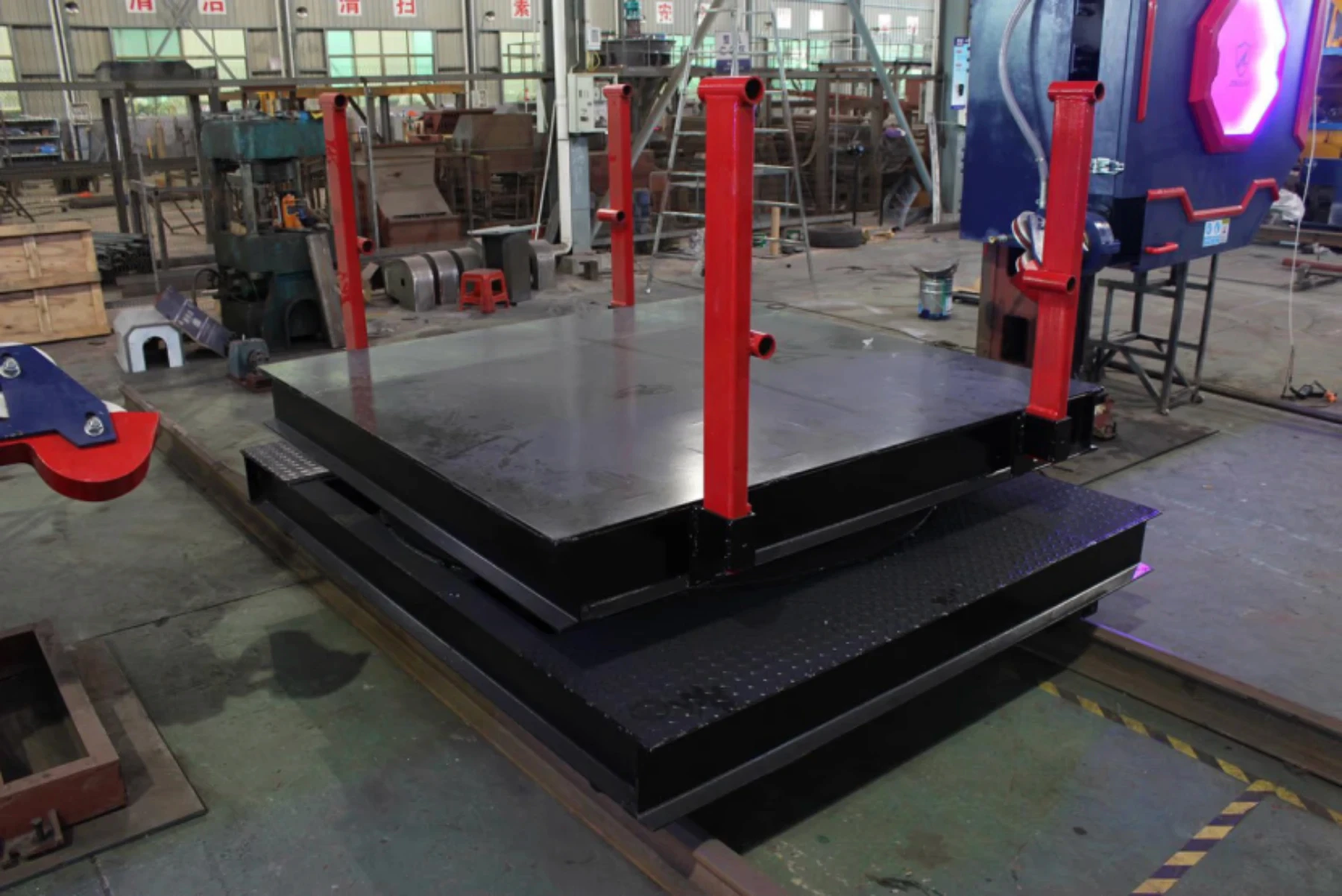

Durable worktable lifespan of up to 10 years

Heavy-duty H-beam welded structure for the worktable, with high-strength slewing bearings for rotating parts, supports a maximum load of 50 tons, designed for a 10-year lifespan.

High-quality and durable accessories

Rails are sourced from Taiwan's HIWIN, bearings from NSK, and flywheel guards are made of lightweight, deformation-resistant, corrosion-resistant fiberglass, significantly extending service life.

Flexible customization options

Customizable rotating carts, gantry tracks, and electrical configurations to meet diverse processing scenarios.

Application Scenarios of CNC Diamond Wire Saw Cutting Machine

Granite mosaic cutting

Granite special-shaped pattern cutting

Granite block splitting

Granite tombstone cutting into finished products

Foam ceramic decorative molding cutting

Foam ceramic square railing cutting into finished products

Product Details of CNC Diamond Wire Saw Cutting Machine

CNC Diamond Wire Saw Cutting Machine operating system

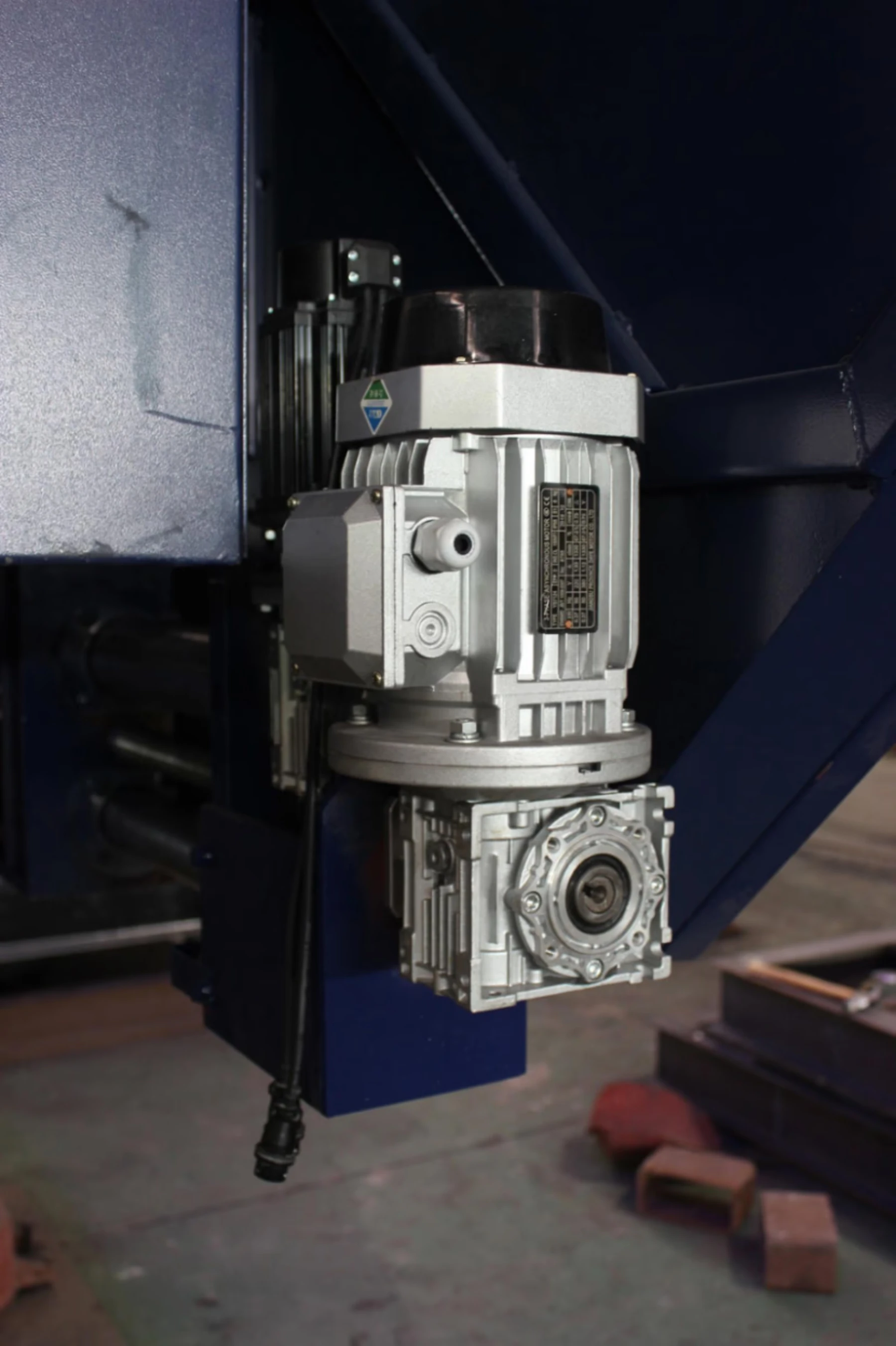

Inovance servo motor

Permanent magnet synchronous motor

Enhanced flywheel design

Cast frame structure

Heavy-duty worktable

Related Products

Intelligent Block Squaring Wire Saw Machine

Features:

The machine adopts a high-efficiency and stable PLC control system, supporting precise trimming and cutting of stone blocks. It is simple to operate, highly efficient, and significantly reduces stone waste while ensuring processing accuracy. The system can be upgraded to the Dinosaw CNC control system, enabling special-shaped cutting for enhanced versatility.

Application Scenarios:

Suitable for medium and large stone processing plants, primarily for trimming and cutting stone blocks. Especially ideal for customers requiring efficient mass production and high cutting precision.

Vertical Diamond Wire Saw Cutting Machine

Features:

Compact design supporting straight-line, arc-edge, and special-shaped cutting, offering excellent cost performance.

Application Scenarios:

Ideal for small and medium-sized stone processing plants, used for fine processing of small to medium materials and tombstones, particularly for customers with low batch production requirements.

Curbstone Wire Saw Cutting Machine

Features:

Supports straight and curved cutting, equipped with conveyor belt transport functionality, enabling automated production lines.

Application Scenarios:

Specially designed for curbstones, roadside stones, and park edging stones, meeting stone processing needs in road construction and landscaping projects.

Multi-Wire Saw Machine

Features:

Supports vertical cutting, capable of batch-cutting stone blocks into slabs with high efficiency and strong cutting stability. The wire saw's narrow kerf significantly improves material yield.

Application Scenarios:

Primarily used for efficient slab production from marble, granite, luxury stone, and sandstone blocks, making it the ideal choice for large-scale stone processing.